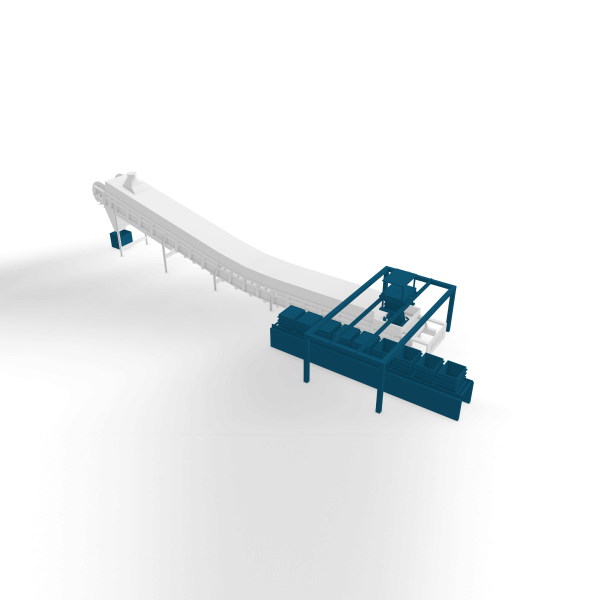

The Superbelt® conveyor

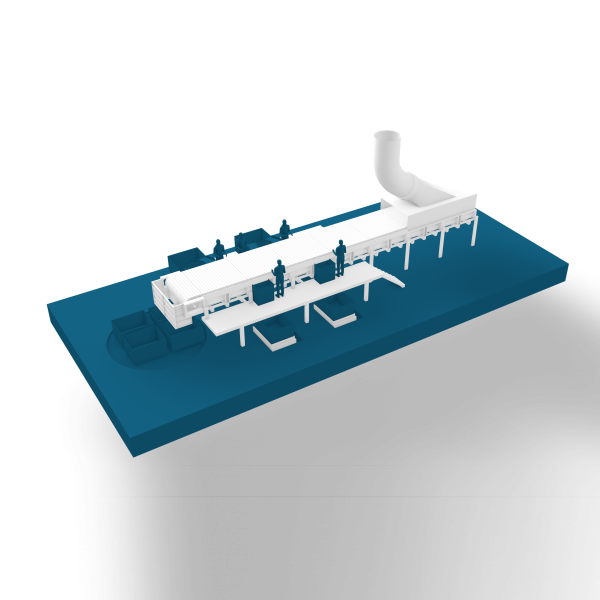

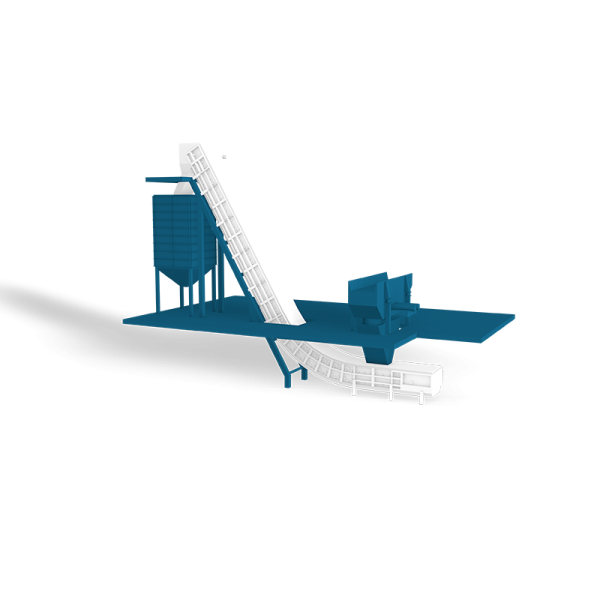

An effective way to move charge recipes from the scrap storage bay to the holding hopper on the melt deck

Conventional conveyors and material handling systems may be used to charge furnaces or carry heavy loads, but cannot withstand heat and repeated impacts over time.

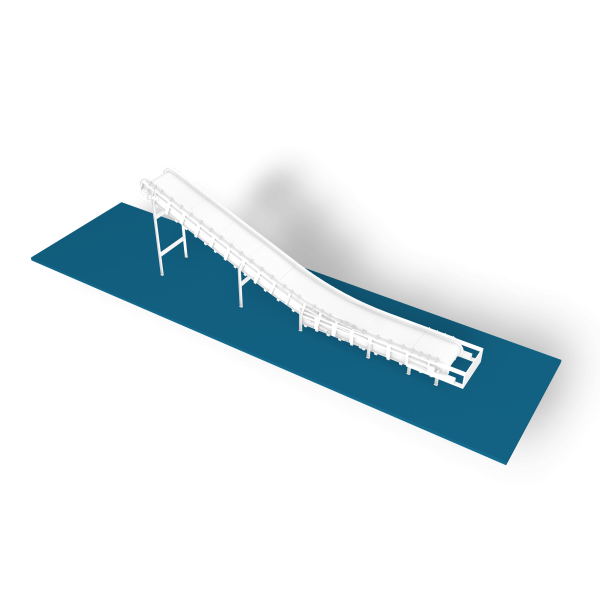

The Superbelt® conveyor differs from all competing technologies. Engineered to withstand the harshest operating conditions, it is effective for transporting heavy materials without spillage or damage and can endure heat stress under high-heat furnace work environments.

High reliability

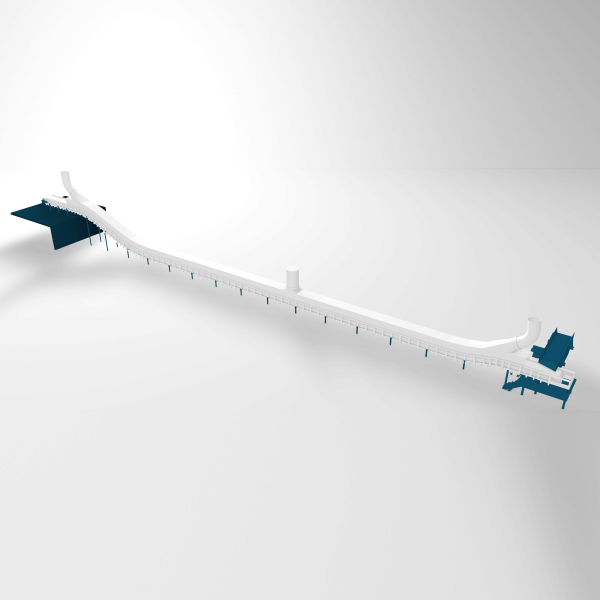

The Superbelt® conveyor is made up of partially overlapping steel pans securely bolted on a patented steel double-wire mesh system.

The belt design is based on a multi-link concept that ensures redundancy, little to no maintenance, and trouble-free continuous operation. Even if the mesh is severely damaged, the conveyor will keep on running till the scheduled maintenance, without sudden failures.

The trouble-free operation allows to preserve the productivity and profitability of the whole plant and results in greater efficiency and uptime during 24/7, year-round operation.

Impact toughness

The supporting structure of the belt is suitable for heavy impacts thanks to the unique shock-absorbing design. The conveyor is supported by specially designed carrying idlers along its full width. At the loading points, the carrying idlers can be closely spaced.

The loading section and the belt itself can be made of manganese steel to assure the highest resistance to both corrosion and deformation. The pans are generally made of manganese steel with 400 HB hardness and 8+8 mm in thick.

Heat and wear resistance

Melting operations can be brutal on conveyor systems due to the high-temperature environment. The exposure to heat causes thermal expansions that must be mitigated and a significant deterioration in wear resistance.

With the Superbelt® conveyor, all issues related to heat are solved thanks to the patented method of connecting the pans to the mesh belt, which leaves all components free to thermally expand in any direction without permanent deformations. The result is a conveyor able to withstand temperatures of up to 1100 °C without affecting the abrasion resistance.

High safety levels

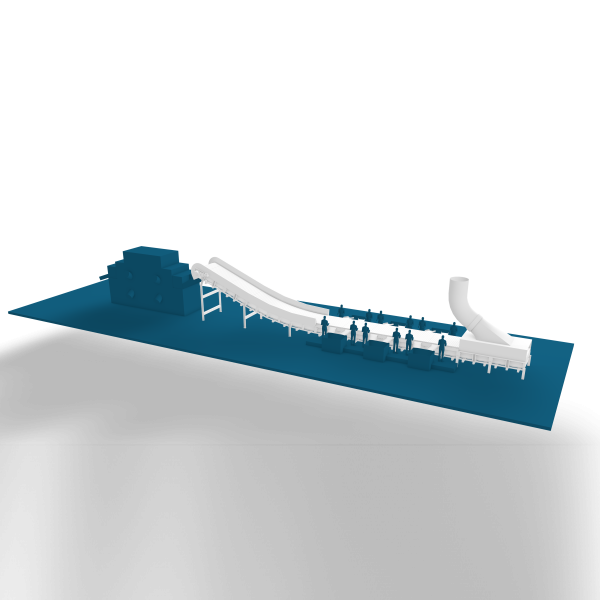

By eliminating manual processes for moving scrap, the Superbelt® conveyor inherently improves workplace safety. Forklift traffic is reduced, production becomes more ergonomic, and operators are kept a safe distance away from the high temperatures of melting furnaces.

Additionally, the risk of material spillage is virtually eliminated thanks to the high skirtboards that follow the belt sidewall profile along its entire length, allowing the containment of even the largest surges of material.

Optional charge pre-heat

Charge recipe pre-heating influences the energy balance and the productivity of the melting furnace positively.

Thanks to the Superbelt® technology, it can be performed - as an option - on the conveyor system.

Before reaching the melting furnace, the charge recipe enters the preheating chamber to be dried (if necessary) and heated-up by a battery of gas burners. The chamber is divided into different zones where burner heat rates can be independently adjusted to control the material temperature better and provide flexibility for sequencing during indexing the material load for each charge batch.

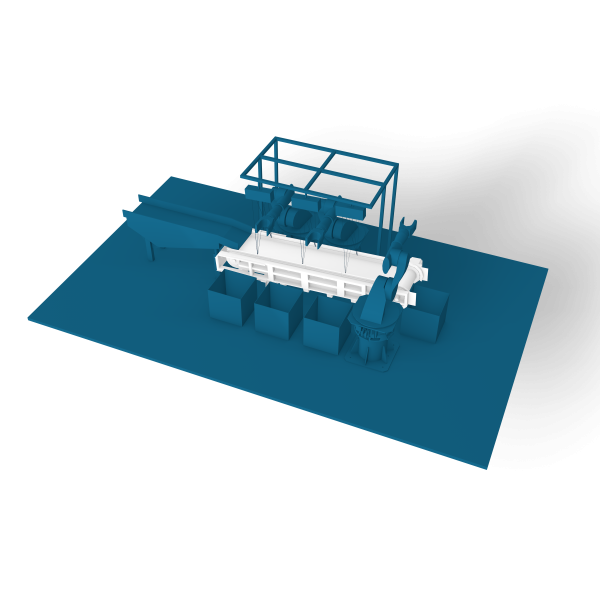

Optional material weighing

The Superbelt® conveyor can also allow for optional material weighing. In this case, the weigh belt section is equipped with a special frame with load cells and an electronic control unit for real-time mass and rate calculations.

The actual material rate is determined by combining the belt speed, monitored by an encoder, and the weight signal given by the load cells.

Some successful stories

Italy

Furnace feeding

Iron foundry

Maintenance efforts have been drastically reduced and the Customer is faced with less operating expenses and less downtime.

The Customer

Foundry specialized in manufacturing ductile iron castings for sanitary and domestic applications.

The Challenge

The apron conveyor used to feed the EAFs was experiencing breakdown after breakdown. The foundry reached out to Magaldi in search of a more reliable solution.

Ten years earlier, Magaldi had installed a Superbelt® conveyor downstream the shot-blasting machine for casting sorting and sprue removal through hydraulic wedges. After experiencing the benefits provided by the Superbelt® technology, they had no doubts and placed a new order with Magaldi.

The Solution

A 30° inclined Superbelt® conveyor moves sprues from the weighing hopper up to 2 EAFs, in a very reliable way. The Customer reported that maintenance efforts have been drastically reduced and they are faced with less operating expenses and less downtime.

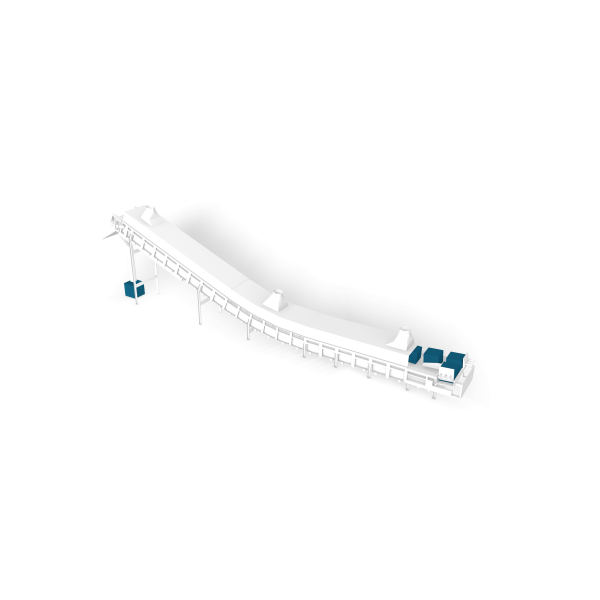

Mexico

Furnace feeding

Copper foundry

The Superbelt® conveyor drastically reduced safety risks by eliminating forklift traffic and scrap contact with operators.

The Customer

One of the world’s largest producers of copper from scrap.

The Challenge

To replace the existing furnace feeding system, responsible for safety hazards.

A forklift tilting skip discharged copper scrap in a vibrating feeder. This process posed safety concerns since the vibrating platform was too high to be reached easily and safely.

The Solution

The Superbelt® conveyor is equipped with a tailored loading hopper, installed in a pit to allow operators to feed the furnace easily and manage the system in batches.

Despite the steep slope (35°), copper bales are transported smoothly thanks to the proper edge of the pans and some cleats, which help the material not to roll backward.

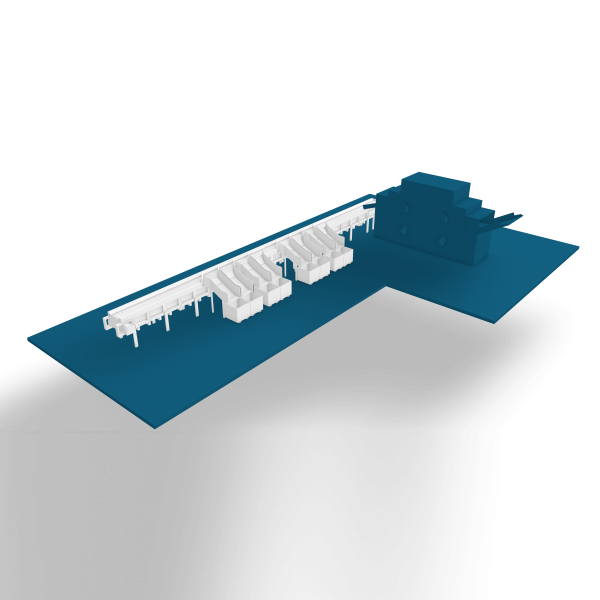

India

Furnace feeding

Iron foundry

The Superbelt® conveyor decreased cycle times and increased safety by automatically transporting scrap, eliminating operators' involvement and allowing them to be distanced from the heat source.

The Customer

Automotive ferrous casting parts maker.

The Challenge

To feed the furnace in total safety for operators.

The Solution

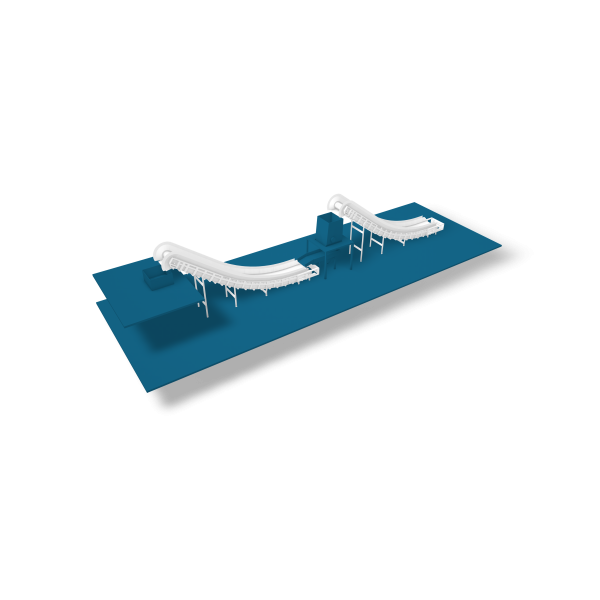

Initially intended to feed the furnace with EOT cranes, the Customer changed his mind and installed two Superbelt® conveyors, able to better control the furnace feeding process.

Magaldi had already replaced a vibrating conveyor installed between the DISA cooling drum and the shot-blasting machine, responsible for frequent damage to castings. A Superbelt® had solved the issue and allowed to carry out casting degating on the same conveyor. A second Superbelt® conveyor had been installed downstream of the shot-blasting machine for casting sorting.