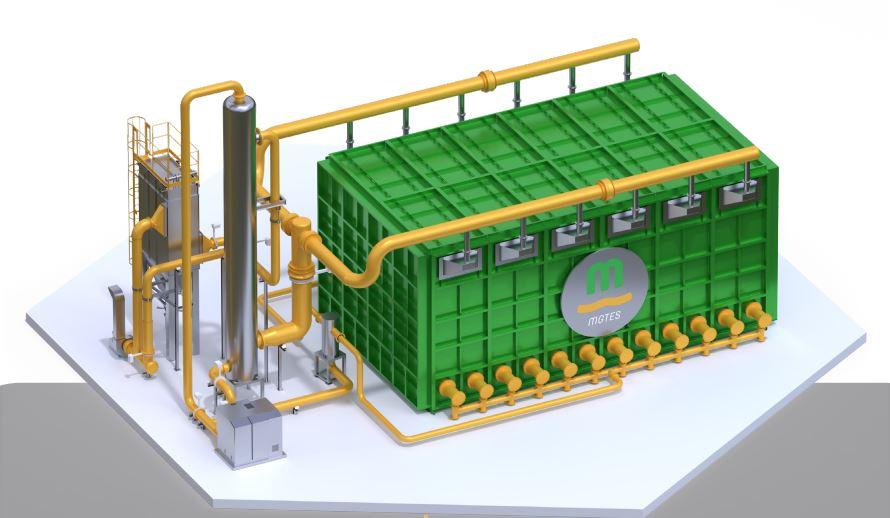

Magaldi Thermal Energy Storage (MGTES)

Based on fluidized sand bed technology, MGTES (Magaldi Green Thermal Energy Storage) stores thermal energy from renewable sources or directly from the grid when electricity prices are low - and dispatches it when needed.

According to the International Energy Agency (IEA), heat remains the largest end-use sector, representing almost half of global final energy consumption and nearly 40% of energy-related CO₂ emissions in 2023.

Yet, around 75% of industrial heat demand is still supplied by fossil fuels - a clear signal of the urgent need to decarbonize industrial processes. Magaldi has developed MGTES, a Power-to-Heat (P2H) system that generates combustion-free thermal energy directly usable in industrial applications to address this challenge.

By storing energy from renewable electricity or the grid when prices are favorable, MGTES not only optimizes renewable utilization but also enhances grid stability.

Working concept

MGTES stores energy in silica sand for hours, days, or even weeks, ensuring continuous availability of green heat.

Each system is composed of insulated modules filled with heated silica sand and operates through three main phases:

- Charging – Renewable or grid electricity powers heaters that charge the system. The sand particles are fluidized, allowing uniform heat transfer.

- Storing – Fluidization stops, and the sand naturally settles. Thanks to the high insulation and lack of convection, heat losses are minimized.

- Discharging – The stored heat is released to produce superheated steam, ready to feed industrial processes.

Key features

- SUSTAINABILITY – Built primarily from silica sand and steel, MGTES is environmentally friendly, containing no toxic or polluting substances

- EFFICIENCY – Thermal energy can be stored for several hours, days, or even weeks

- MODULARITY – The system can connect to the electrical grid, solar PVs, or both. Its modular design allows tailored configurations to match customer needs

- FLEXIBILITY – MGTES supports simultaneous charging and discharging, ideal for processes requiring a stable baseload of steam

Main applications

MGTES provides green heat 24/7, replacing fossil fuels in industrial processes operating between 150°C and 600°C, including pulp & paper, food & beverage, chemical, pharmaceutical, textile, mining, and district heating sectors.

If you’re looking for a modular, resource-efficient, reliable, and flexible solution to meet your industrial steam demand, discover how MGTES can help you decarbonize your operations.

Power-to-Heat | Magaldi Green Energy

Find out more