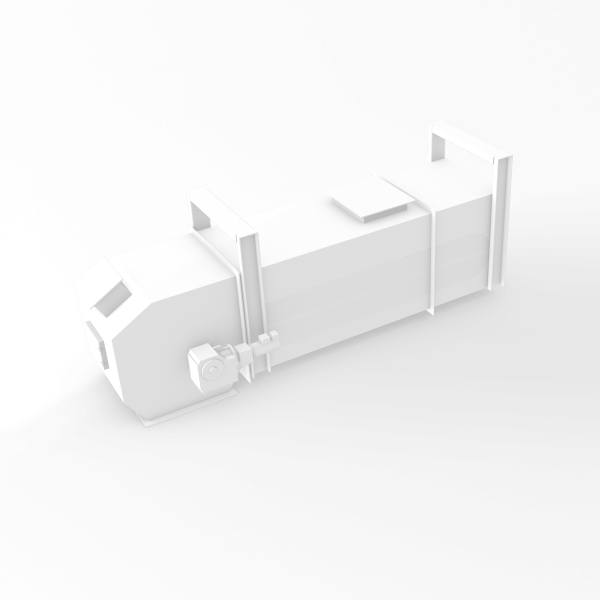

Single Roll Crushers

Superior performance in high temperature, dry applications

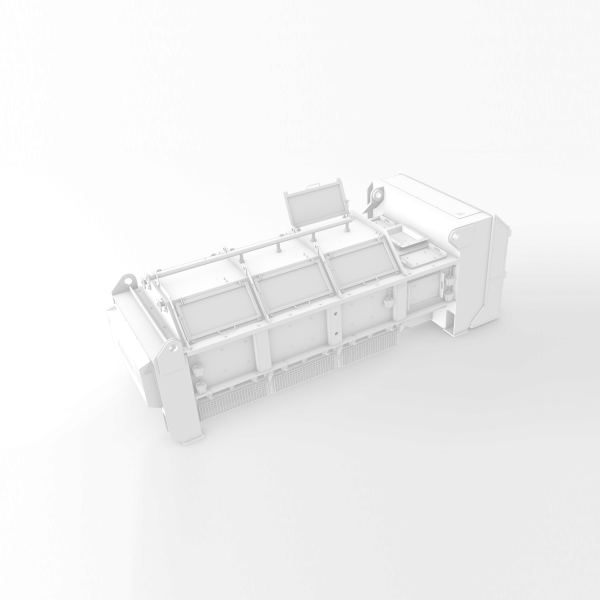

Even if they have long been used in dry bottom ash applications, the Magaldi Single-Roll crushers are suitable to operate under severe conditions to handle the broadest possible range of materials (waste heat boiler slag, big lumps, and bottom ash), effectively reducing the material size and providing high efficiency, reliability, and uptime while considerably lowering the percentage of fines.

Magaldi has developed many tailored solutions. The product family consists of models of different sizes (27’’, 54’’, 67’’, 81’’) depending on the required final particle size and capacity.

Working concept

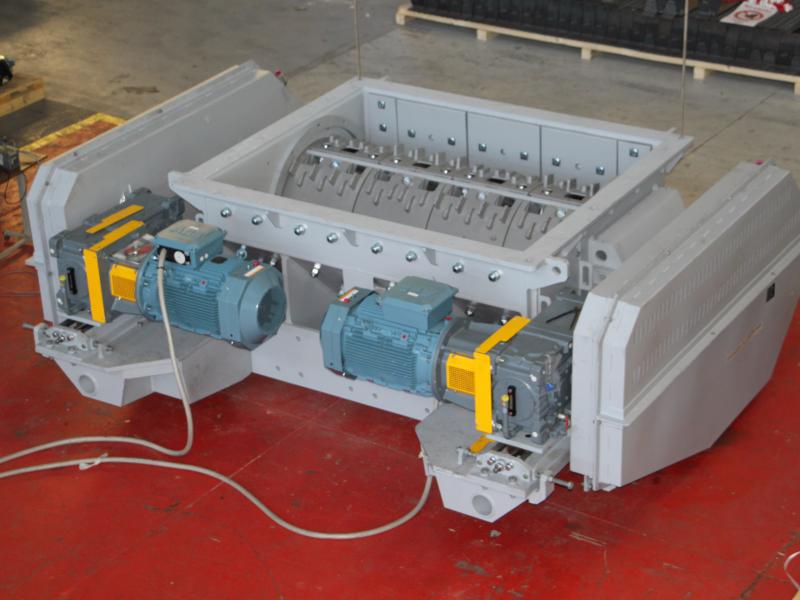

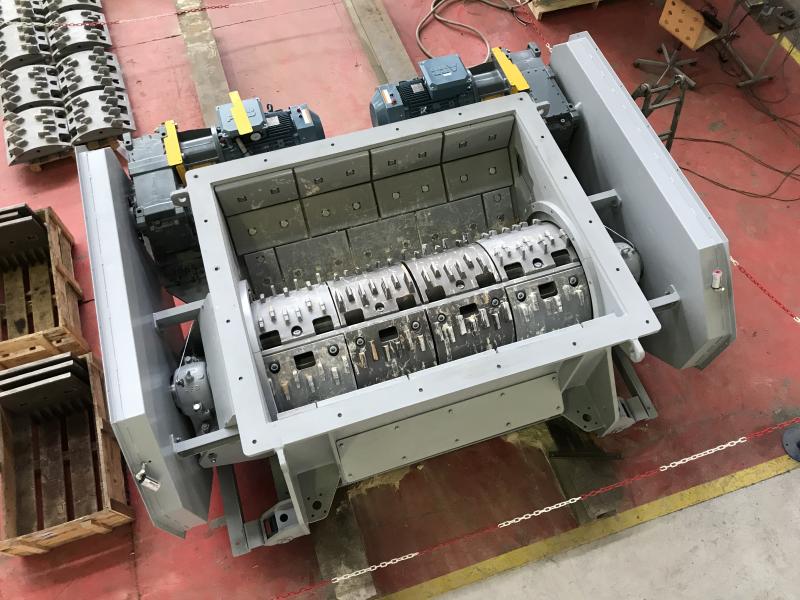

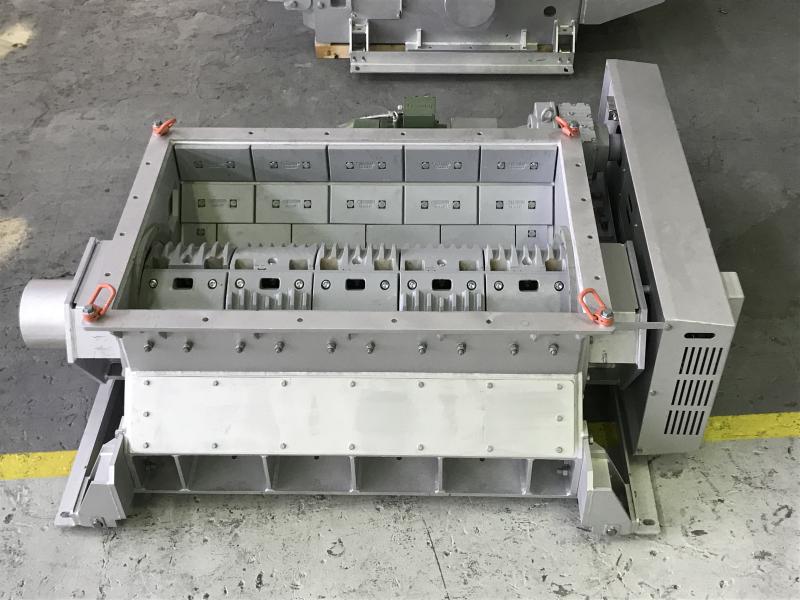

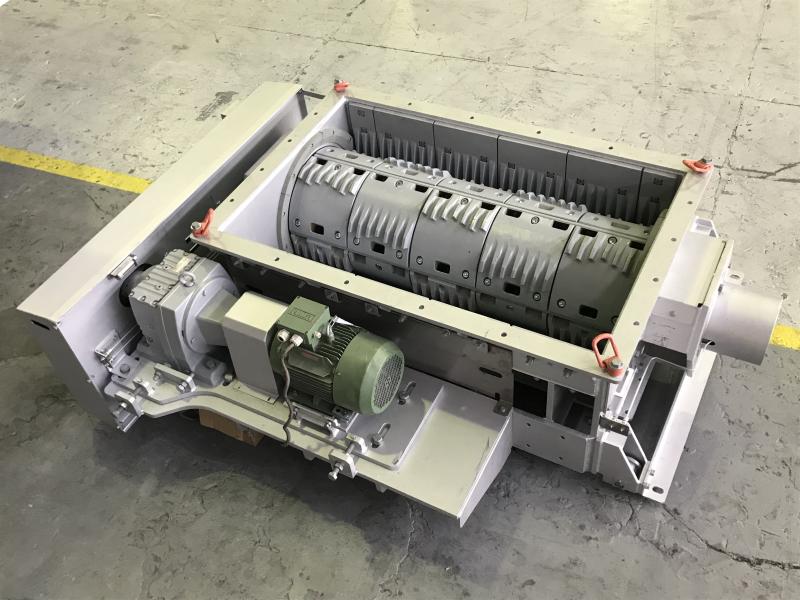

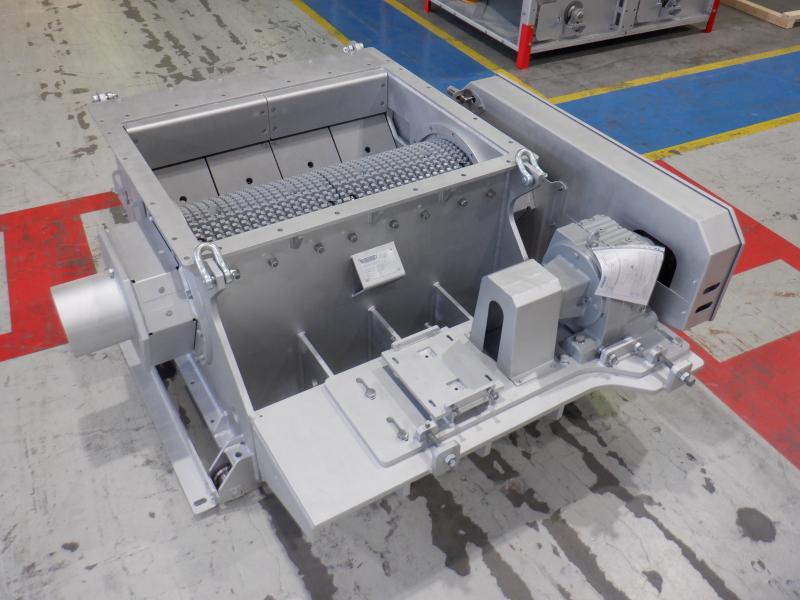

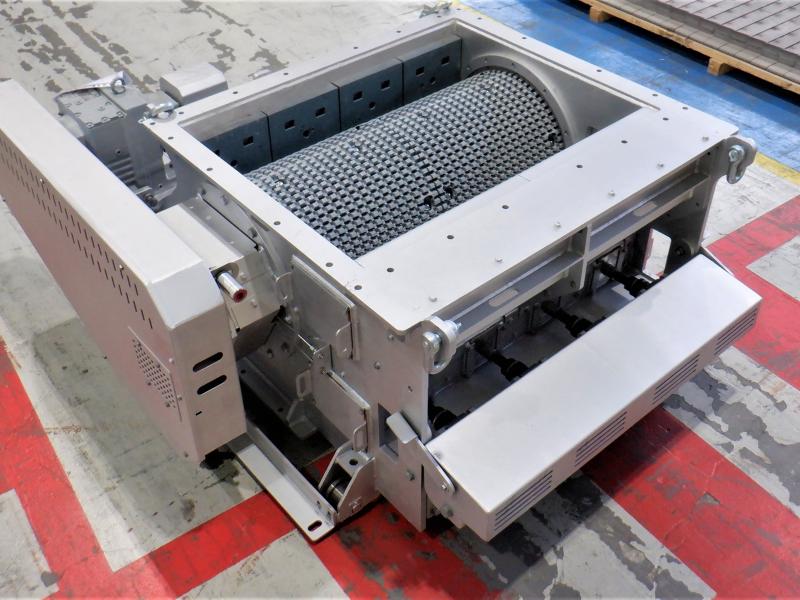

Magaldi Single-Roll Crusher features a toothed roll assembly, which crushes the incoming feed material against anvil plates.

When the material enters through the inlet chute, the teeth of the rotating cam shear and split the chunks against the anvil plates. The crushed material is cleared and dropped down, through the crusher outlet chute, into a collecting bin or conveying equipment.

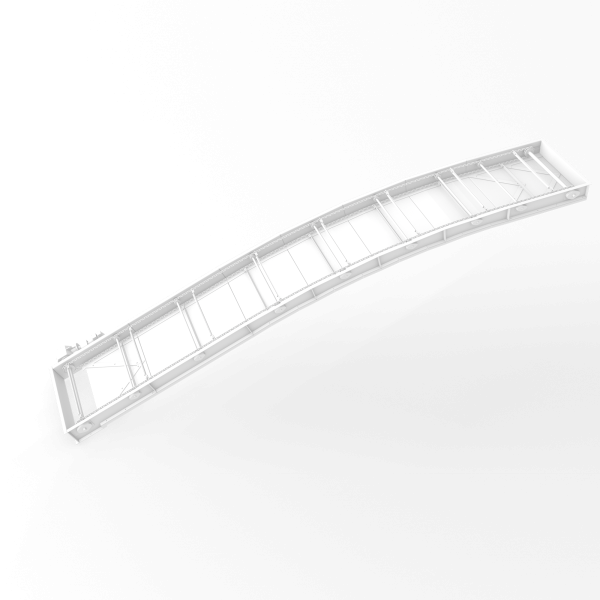

The clearance between the roll and the anvil plates can be adjusted to set the maximum particle size at the crusher outlet.

Compact & rugged design

The core of Magaldi Crusher is a single-roll cam, whose design produces more crushing force than a double-roll design while reducing initial cost and power consumption.

Mounted on a bracket, the drive has a very compact arrangement, requiring lower room for installation.

The electrical motor and the gear reducer are connected through a flexible coupling to absorb eventual shocks, vibrations, and misalignments between the above components.

High temperature applications

Magaldi crushers are designed to work in the most severe conditions, including temperatures up to 350 °C.

Cams and anvil plates are made of high-chromium wear-resistant white cast iron to preserve hardness at high temperatures. Sealing is provided through high temperature gasket made out of unique grade silicon rubber

High throughput capacity

With a maximum rate of 500 t/h, Magaldi crushers have the highest throughputs among primary crushers.

The crushing action is carried out along the full width of the curved anvil plate, ensuring maximum throughput capacity.

Effective grinding

The rugged construction and design guarantee the highest performance, even with very hard materials.

Square profile teeth provide effective shearing, while the anvil plate arrangement allows for producing upright forces at all angles where there is contact among cams, material, and plates, thus assuring an effective size reduction.

Ease of inspection & maintenance

Magaldi crushers are designed to last: cams are engineered for severe-duty applications to prevent loosening and unnecessary wear, while anvil and plates increase wear life and reduce maintenance.

They also meet the highest safety standards. Safety guards are installed on moving parts, and all components and parts (rolls, shafts, bearings, lubrication devices) requiring inspection and renewal are engineered to be easily and safely accessible and replaceable when needed.

Primary Crushers (single-roll, double drive)

| Model N° | FRT 54'' | FRT 67'' | FRT 81'' |

|---|---|---|---|

| Rotor DN (mm) | 600 | 600 | 900 |

| Design rate (t/h) | 15÷150 | 20÷200 | 75÷500 |

| Output particle size (mm) | 80 | 80 | 120 |

| Feed product temp. (°C/°F) | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over |

| Operating speed (RPM) | 15÷60 | 15÷60 | 15÷60 |

| Motor power (kW) | 2 x (7,5÷18,5) | 2 x (11,22) | 2 x (37,5÷55) |

| Drivetrain | 2 x (electrical motor + coupling + gearbox + chain transmission) | 2 x (electrical motor + coupling + gearbox + chain transmission | 2 x (electrical motor + coupling + gearbox + chain transmission |

| Flange-to-flange height (mm) | 810 | 810 | 1200 |

| Inlet opening (mm) | 1370 x 1090 | 1700 x 1090 | 2055 x 1635 |

| Overall dimension (mm) | 3085 x 2600 x 870 | 3085 x 2940 x 870 | 3855 x 3060 x 1320 |

| Body material | mild steel/stainless steel | mild steel/stainless steel | mild steel/stainless steel |

| Wear Plate Material | special chromium-enriched cast iron | special chromium-enriched cast iron | special chromium-enriched cast iron |

| Weight (double drive) | 5000 | 6400 | 15000 |

| Speed Regulation | optional (with frequency converter) | optional (with frequency converter) | optional (with frequency converter) |

Primary Crushers (single-roll, single drive)

| Model N° | FRT 27'' | FRT 54'' | FRT 67'' | FRT 81'' |

|---|---|---|---|---|

| Rotor DN (mm) | 600 | 600 | 600 | 900 |

| Design rate (t/h) | 5÷30 | 15÷60 | 20÷75/110 | 75÷300 |

| Output particle size (mm) | 80 | 80 | 80 | 120 |

| Feed product temp. (°C/°F) | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over |

| Operating speed (RPM) | 15÷60 | 15÷60 | 15÷60 | 15÷60 |

| Motor power (kW) | 7,5÷11 | 7,5÷18,5 | 11÷22 | 37,5÷55 |

| Drivetrain | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission |

| Flange-to-flange height (mm) | 810 | 810 | 810 | 1200 |

| Inlet opening (mm) | 690 x 715 | 1370 x 1090 | 1700 x 1090 | 2055 x 1635 |

| Overall dimension (mm) | 2120 x 1800 x 870 | 3085 x 2600 x 870 | 3085 x 2940 x 870 | 3855 x 3060 x 1320 |

| Body material | Mild steel / Stainless steel | Mild steel / Stainless steel | Mild steel / Stainless steel | Mild steel / Stainless steel |

| Wear Plate Material | Special chromium-enriched cast iron | Special chromium-enriched cast iron | Special chromium-enriched cast iron | Special chromium-enriched cast iron |

| Weight | 2600 | 4500 | 5900 | 12700 |

| Speed Regulation | Optional (with Frequency Converter) | Optional (with Frequency Converter) | Optional (with Frequency Converter) | Optional (with Frequency Converter) |

Secondary Crushers (single-roll, single drive)

| Model N° | FRT 27'' | FRT 54'' | FRT 67'' |

|---|---|---|---|

| Rotor DN (mm) | 600 | 600 | 600 |

| Design rate (t/h) | 5÷30 | 15÷60 | 20÷75/110 |

| Output particle size (mm) | 25 | 25 | 25 |

| Feed product temp. (°C/°F) | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over |

| Operating speed (RPM) | 30÷120 | 30÷120 | 30÷120 |

| Motor power (kW) | 7,5÷11 | 11÷22 | 15÷30 |

| Drivetrain | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission |

| Flange-to-flange height (mm) | 810 | 810 | 810 |

| Inlet opening (mm) | 690 x 715 | 1370 x 1090 | 1700 x 1090 |

| Overall dimension (mm) | 2120 x 1800 x 870 | 3085 x 2600 x 870 | 3085 x 2940 x 870 |

| Body material | Mild steel / Stainless steel | Mild steel / Stainless steel | Mild steel / Stainless steel |

| Wear Plate Material | Special chromium-enriched cast iron | Special chromium-enriched cast iron | Special chromium-enriched cast iron |

| Weight | 2600 | 4500 | 5900 |

| Speed Regulation | Optional (with Frequency Converter) | Optional (with Frequency Converter) | Optional (with Frequency Converter) |

Secondary Crushers (single-roll, single drive, adjustable)

| Model N° | FRT 27'' | FRT 54'' |

|---|---|---|

| Rotor DN (mm) | 600 | 600 |

| Design rate (t/h) | 5÷30 | 15÷60 |

| Output particle size (mm) | 25 | 25 |

| Feed product temp. (°C/°F) | 900°C and over/ 1652°F and over | 900°C and over/ 1652°F and over |

| Operating speed (RPM) | 30÷120 | 30÷120 |

| Motor power (kW) | 7,5÷11 | 11÷22 |

| Drivetrain | Electrical Motor+ Coupling+Gearbox + Chain transmission | Electrical Motor+ Coupling+Gearbox + Chain transmission |

| Flange-to-flange height (mm) | 810 | 810 |

| Inlet opening (mm) | 690 x 715 | 1370 x 1090 |

| Overall dimension (mm) | 2120 x 1800 x 870 | 2815 x 2260 x 1075 |

| Body material | Mild steel / Stainless steel | Mild steel / Stainless steel |

| Wear Plate Material | Special chromium-enriched cast iron | Special chromium-enriched cast iron |

| Weight | 2860 | 6100 |

| Speed Regulation | Optional (with Frequency Converter) | Optional (with Frequency Converter) |