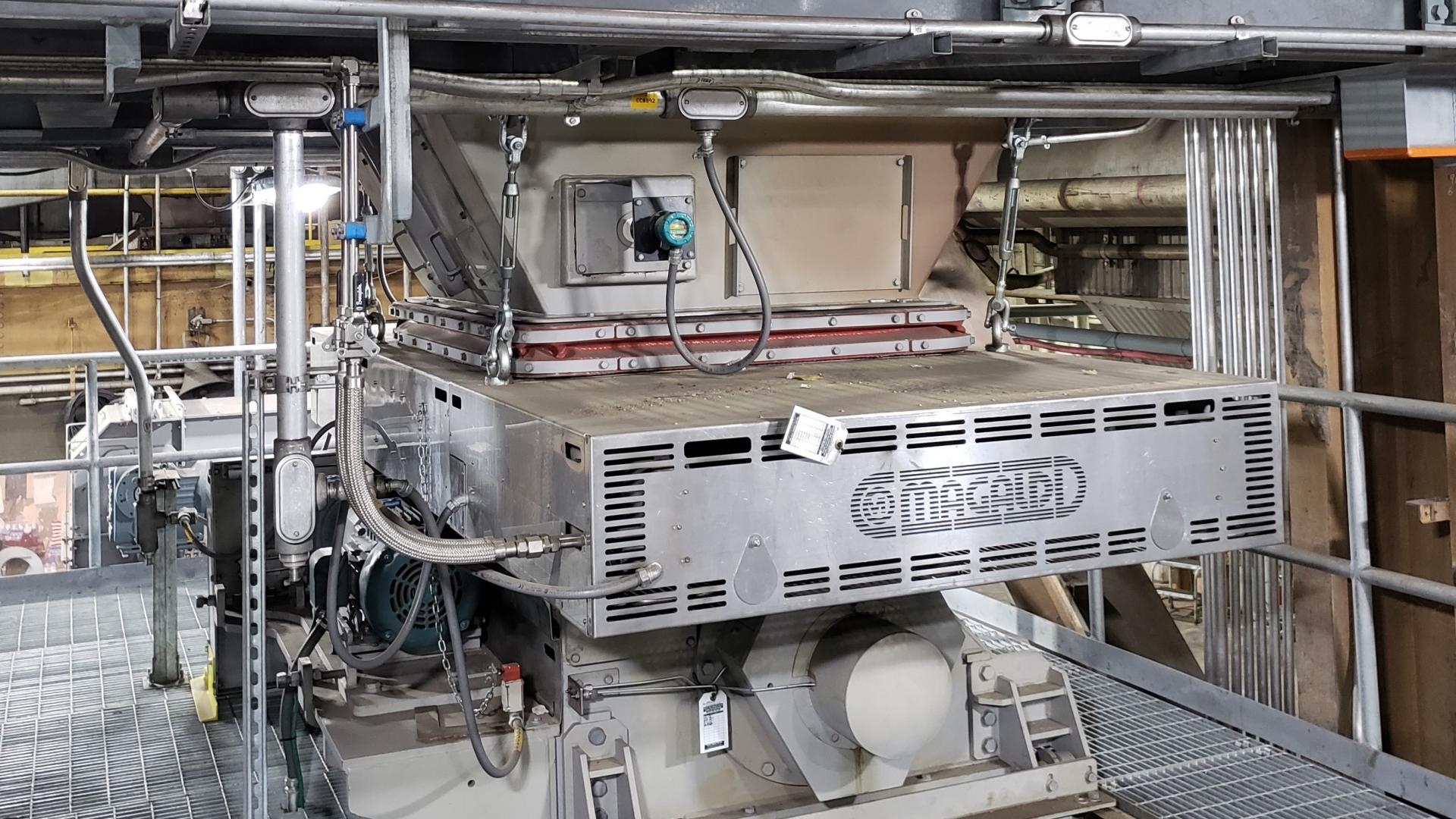

Designed for heavy-duty, round-the-clock performance, Magaldi foundry equipment covers virtually all applications where extreme reliability is critical.

Your Partner for Turnkey Conveying Solutions and Equipment

Dependable technologies since 1929

Your Partner for Turnkey Conveying Solutions and Equipment

Dependable technologies since 1929

Your Partner for Turnkey Conveying Solutions and Equipment

Dependable technologies since 1929

Your Partner for Turnkey Conveying Solutions and Equipment

Dependable technologies since 1929

Research & Development

Dependability and Innovation are part of our DNA

Innovation is key to Magaldi’s competitive advantage. Along with dependability, it has historically been the focus of the entrepreneurial culture and the pillar of a business model aimed at turning innovative ideas into viable solutions.

Industries

Aluminum processing

Magaldi designed and developed fully integrated solutions for the effective handling of both cold scrap and hot shreds, to improve the smelting process under a more environmentally friendly and sustainable economic model.

Industries

Metallurgy

Manufactured to endure the harsh conditions in the steel and metal recycling industry, Magaldi heavy-duty conveyors allow to securely and efficiently feed, weigh, and transport hard-to-handle materials.

Industries

Metalworking

Valued for their versatility and low-maintenance operation, Magaldi metalworking conveyors enable to maximize production times, recover by-products, and contribute to safer work environments.

Industries

Cement

In cement plants, Magaldi conveyors transport from very fine to coarse-grained bulk materials, even at high temperatures, over long distances, or across steep inclines, with excellent sealing performance and environmental compliance.

Industries

Power & Heat

Recognized as Best Available Technologies (BAT) for the reduction of the environmental risks related to ash handling and cooling, Magaldi dry systems are key to sustainable and profitable ash management.

Industries

Auxiliary equipment

Magaldi also offers auxiliary equipment designed for weighing, crushing, mixing, or cleaning a range of materials in a plurality of industries.

processing

equipment

History

An impressive family tale

Almost a century of dreams, challenges, and successes, among tradition and innovation.

Always taking the best from the past to build the future.

Green Energy

Thermal Energy Storage: The Key to Industrial Heat Decarbonization

Magaldi Green Energy has developed proprietary thermal energy storage technologies that are set to play a crucial role in the global energy transition

Upcoming Events

EUROGUSS

January, 13-15

Nuremberg, GERMANY Booth 4A-416

PowerGen USA

January, 20-22

San Antonio, TX - US Booth 1455

18th Conference Thermal Conversion of Municipal Waste

February, 24-26

Krakow, POLAND

KEY - The Energy Transition Expo

March, 4-6

Rimini, ITALY

European Industrial Energy Days

March, 4-5

Rotterdam, THE NETHERLAND

ExpoAcero 2026

March, 23-25

Veracruz, MEXICO

ChemBio Finland 2026

April, 15-16

Helsinky, FINLAND

AISTech 2026

May, 4-7

Nashville, TN - US Booth 1228

Zellcheming 2026

June, 16-18

Wiesbaden, GERMANY

Aluminum

October, 6-8

Dusseldorf, GERMANY Booth 6K61

Fundiexpo - GIFA 2026

October, 26-30

Monterrey, MEXICO

News

Data-Driven Decisions with Magaldi’s Mobile Test Facility

29 September 2025

Every ton of Incinerator Bottom Ash (IBA) holds untapped metal recovery potential, but uncertainty holds back investment. Magaldi’s Ash Insight Unit, a mobile on-site testing facility, gives Waste-to-Energy operators real data under real conditions, eliminating guesswork and enabling smart, scalable decisions. From accurate feasibility studies to full-scale IBA treatment with the MADAM system, Magaldi turns IBA into opportunity - because smart investment starts with knowing what’s inside.

Read MoreNews

TrAsh or Treasure? The Circular Promise of Dry Ash Management

01 July 2025

Every ton of municipal solid waste processed in WtE plants contains valuable metals hidden within Incinerator Bottom Ash (IBA). Recovering these metals offers a significant opportunity, with potential revenues reaching up to €30 per ton of waste. Moreover, recycling these materials could prevent 20–30 million tons of CO₂ emissions each year. MADAM (MAgaldi Dry Ash Management) system transforms this process by keeping IBA dry, which enhances recovery rates and preserves the quality of the metals. This innovative approach not only increases market value but also contributes to substantial carbon savings.

Read MoreNews

Breaking the Waste Cycle: How Dry IBA Management Can Disrupt Landfill Dependency and Ash Pond Pollution

24 June 2025

We burn waste to keep it out of landfills - but what about the ash? If untreated or poorly managed, Incinerator Bottom Ash (IBA) becomes just another form of waste destined for landfills or ash ponds, thus undermining the circularity promise of WtE systems. The Magaldi Dry Ash Management (MADAM) system tackles this critical gap by drastically reducing the amount of IBA sent to landfill and transforming it into a cleaner, high-quality material suitable for reuse.

Read MoreNews

Every Drop Matters: Rethinking Water Use in IBA Handling

17 June 2025

Water scarcity is a growing global crisis, yet many Waste-to-Energy plants still rely on water-intensive methods to manage incinerator ash, wasting millions of liters annually and risking costly environmental damage. What if there were a way to eliminate water use, slash costs, and boost sustainability? Discover how Magaldi’s revolutionary dry IBA management system, MADAM, is transforming the industry and why this shift could be a game-changer for water-stressed regions worldwide. Dive into the full story to see how every drop truly matters.

Read More

Contact

We can do great things.

Together.