To achieve the most environmentally friendly steel production, switching from the traditional BF-BOF route to scrap-based electric steelmaking is crucial for future-proofing steel plants. While this transition is complex, investing in Electric Arc Furnaces (EAFs) and scrap treatment processes allows steelmakers to manage any necessary logistical changes within the plant while maintaining operational capacity.

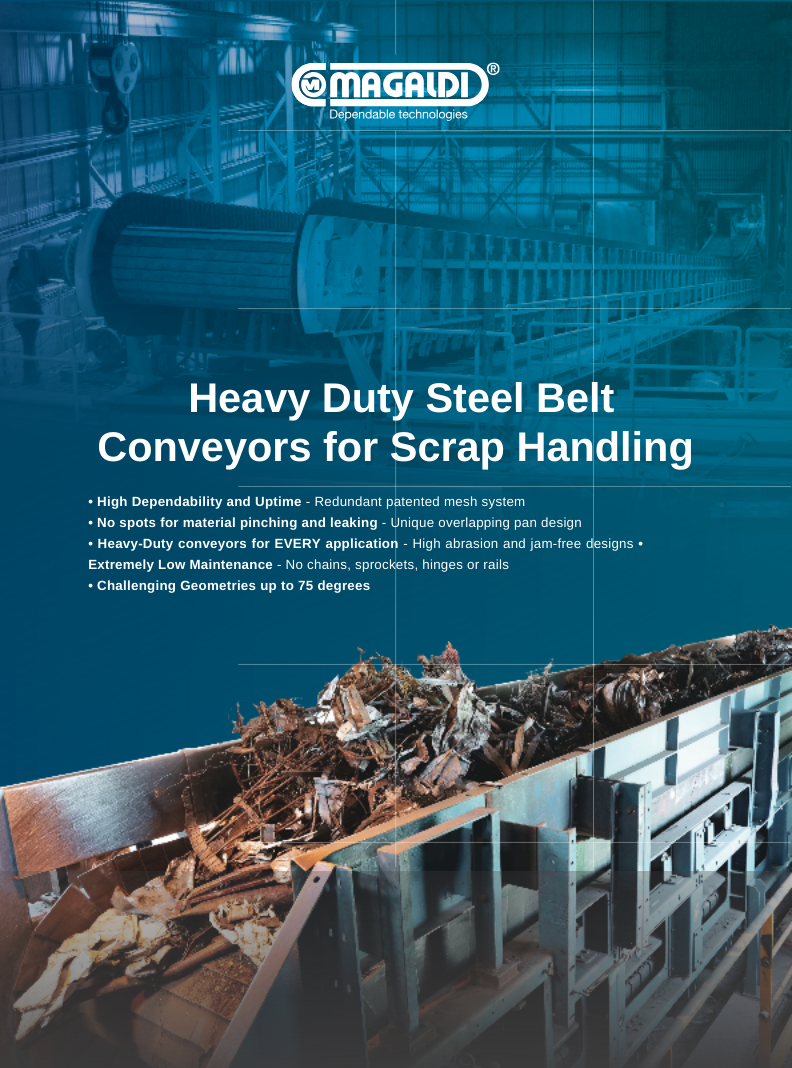

By capitalizing on steel's recyclability, increasing scrap utilization becomes a central focus for achieving green steel production. Magaldi has developed custom-engineered conveyor systems that meet the demands of scrap handling across all phases.

The Magaldi Superbelt® HD (Heavy-Duty) conveyors efficiently transport up to large volumes of scrap metal from yards to various processing equipment (e.g., shredders, crushers, shears, HMS cleaners, etc.) or directly to the furnace, ensuring the highest levels of reliability and uptime, as well as seamless integration into existing operations.

The versatility of the Superbelt® HD conveyors translates into competitive operational costs, as they enable flexibility in input materials, enhance resilience against supply shortages and market volatility, and can be adapted to diverse scenarios.

For a comprehensive understanding of these solutions, download and read the full article published in Recycling Today.

-

The fastest route to zero is through recycling

35.15 Mb - PDFDownload