The Superbelt® conveyor

Engineered to safely and efficiently move castings to, or away from, the blast area

Shot-blasting is an essential part of most foundry operations. Shot peening treatment not only removes the oxide skin and sand from the casting surface to get castings ready for subsequent processing, but it is also essential to ensure their quality by finding the surface defects.

Automating the casting loading and unloading operations with a properly selected conveyor system helps optimize shot blast processes by improving uptime, enhancing productivity, and cutting operating and maintenance costs.

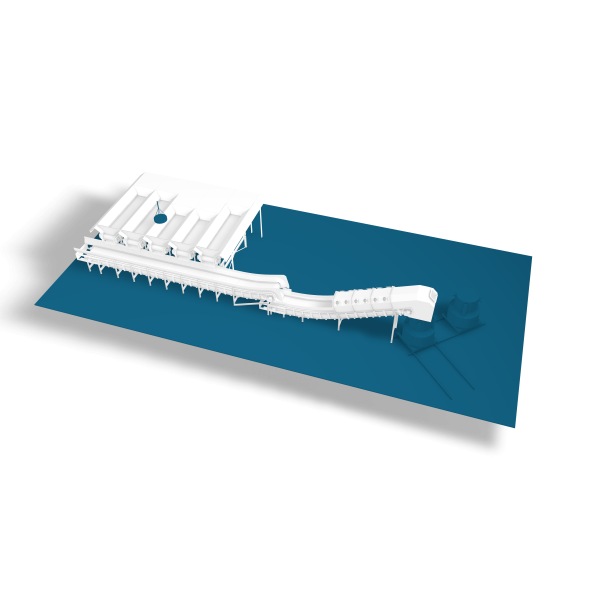

Tailored to meet application requirements, the Superbelt® conveyor offers great flexibility and can be installed in new plants or easily fitted to existing blast equipment.

High reliability

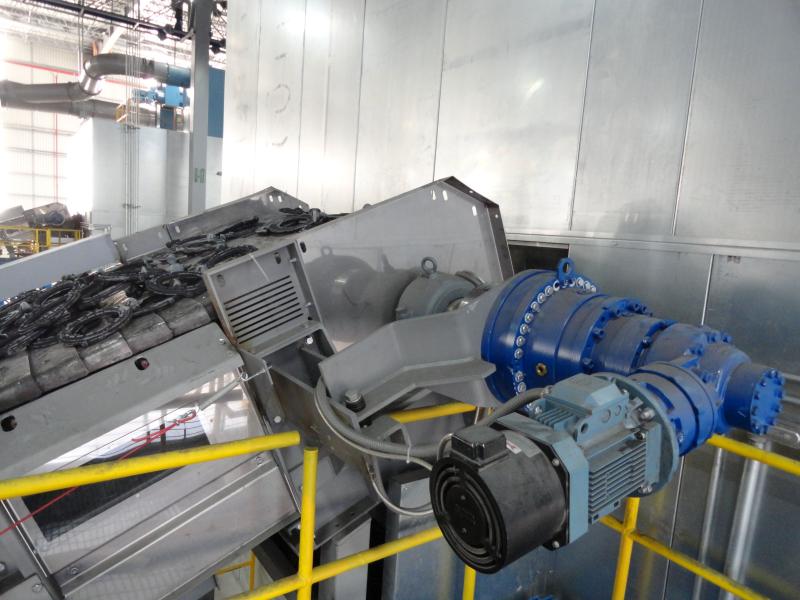

The Superbelt® is a steel belt conveyor made up of partially overlapping steel pans securely bolted on a patented steel double-wire mesh system.

The belt design is based on a multi-link concept that ensures redundancy, little to no maintenance, and trouble-free continuous operation. Even if the mesh is severely damaged, the conveyor will keep on running without sudden failures till the scheduled maintenance.

The unmatched reliability also results in greater efficiency and uptime during 24/7, year-round operation.

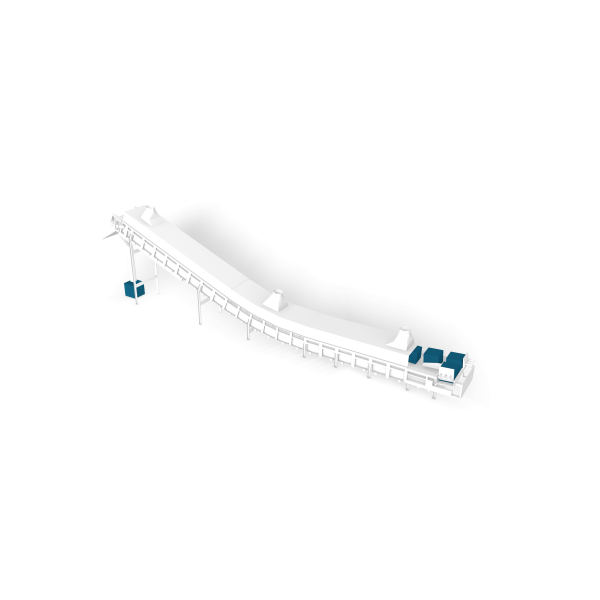

Design flexibility

The plant layout has a direct impact on the choice of the most effective material handling solution.

Available in a wide array of configurations, the Superbelt® conveyor masters any constraint in the facility layout.

Unlike vibratory conveyors, it can safely transport castings on steep inclines/declines without any risk of material slippage. This avoids the shot-blasting machine having to be placed in a pit, and the related costs for civil works.

Reduced silica dust emissions

The Superbelt® conveyor provides a competitive edge in dealing with a highly sensitive issue, namely workers' exposure to crystalline silica dust.

The simple operation of the Magaldi conveyor system ensures smooth running without vibrations which, in turn, minimizes dust emissions, contributing to a safer and healthier work environment.

"All in one":

casting degating & shot-blasting loading

Magaldi allows combining multiple functions and tasks within one conveyor.

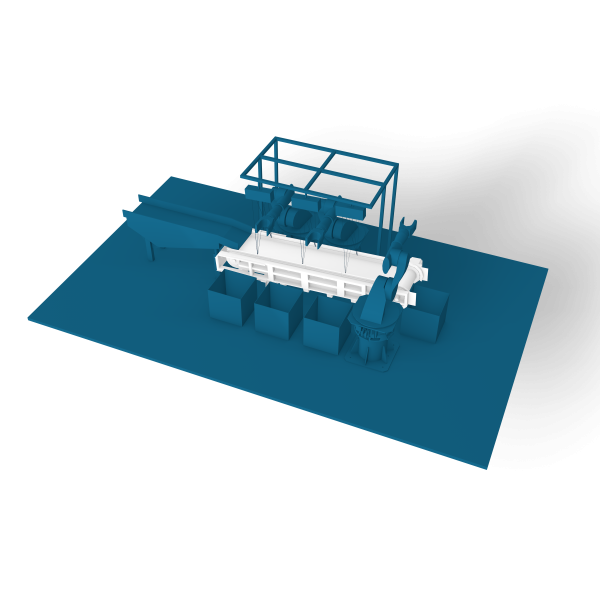

If requested, the Superbelt® conveyor can be used as a workstation for degating the castings as they move to the shot-blasting machine. This results in eliminating process or layout complexity, combining steps to improve efficiency, simplifying maintenance, and saving room.

Blast media recovery

When installed downstream of the shot-blasting machine, the Superbelt® conveyor can be equipped with a static unloading chute to separate and recover the blast media. The chute is designed to effectively separate the blast media and collect them in a skip, while the foreign pieces are unloaded to another skip and thus ready to be remelted.

Low maintenance requirements

The Superbelt® conveyor requires little to no maintenance as it is devoid of critical wear points (no wear bars, pins, hinges, chains, or sprockets). The only points requiring lubrication are the bearings of the head and tail pulley, which can be greased with the belt in operation. The other components are designed for continuous operation and can be checked during preventive maintenance over a multi-year schedule.

Some successful stories

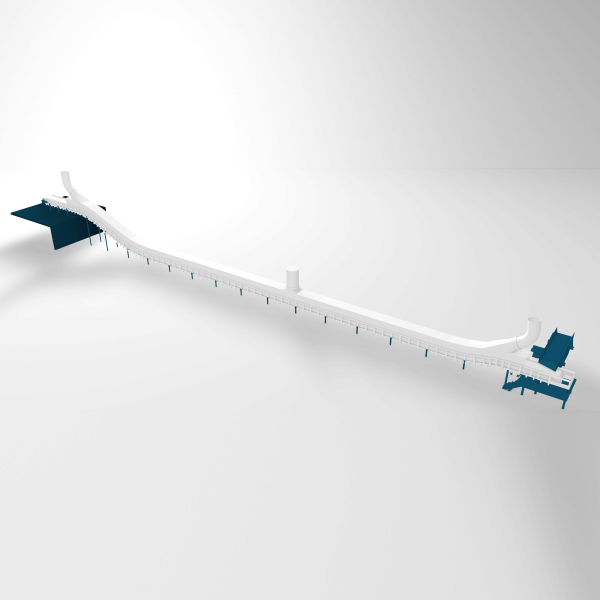

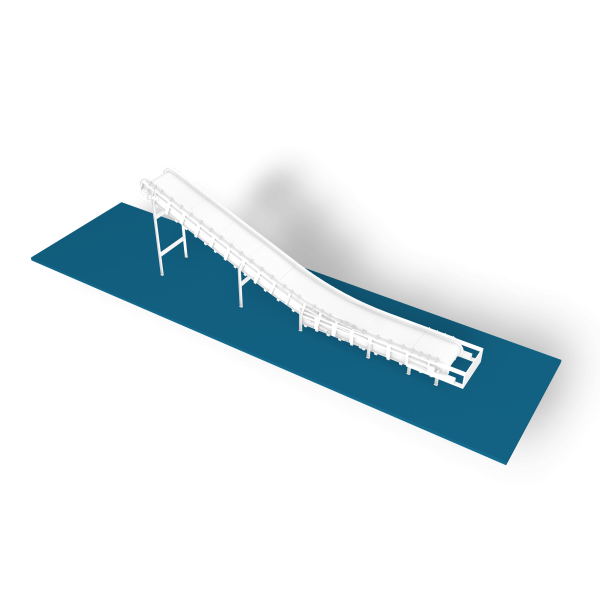

USA

Blast loading

Iron foundry

The Superbelt® integrated with the plant seamlessly and allowed for increased productivity.

The Customer

Foundry specialized in producing gray, ductile, austempered and compacted graphite iron castings for the automotive, agriculture, construction and industrial market.

The Challenge

The plant is part of an industrial group holding 7 foundries. Magaldi had already partnered with the Customer to provide a furnace feeding conveyor, succeeding in improving throughput, increasing profitability and reducing maintenance costs. That is why the Customer awarded Magaldi with a new contract for a conveyor to load the shot blasting machine.

The Solution

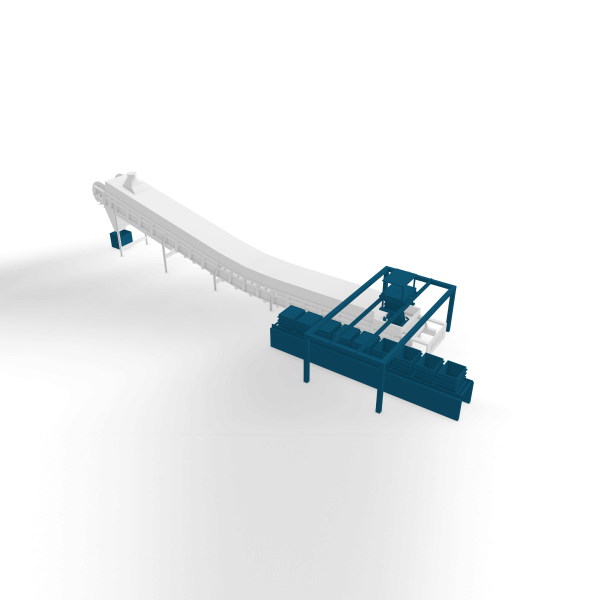

Magaldi custom engineered a Superbelt® conveyor to handle the job. A 12m long conveyor moves castings from the cooler discharge up to the shot-blasting machine, ensuring a dependable and smooth operation.

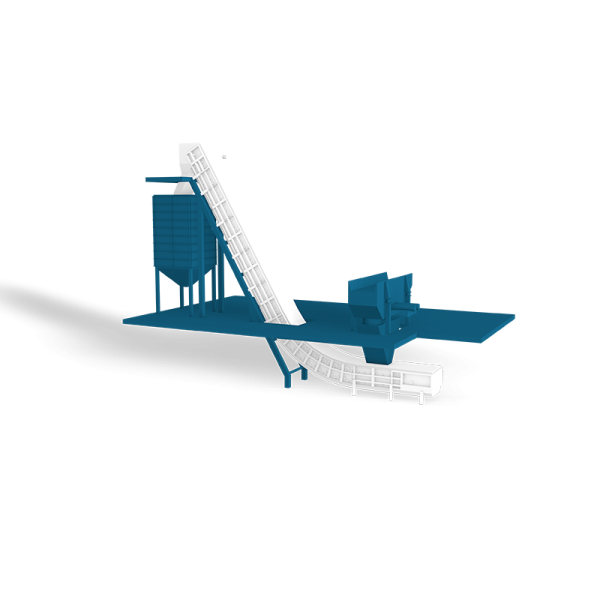

Mexico

Blast loading

Iron foundry

The foundry drastically reduced maintenance hassles to such an extent that they don’t remember they have a belt to convey castings.

The Customer

World’s largest producer of suspension components for light commercial vehicles and the only fully integrated brake rotor producer in America.

The Challenge

The Customer had to deal with several maintenance issues and unexpected failures of the existing chain conveyor used to load the continuous shot-blasting machine.

The Solution

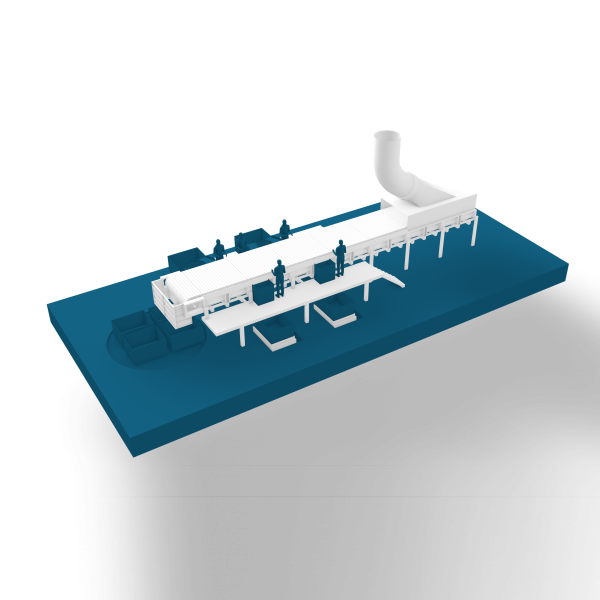

A 28m long Superbelt® conveyor receives disc brakes discharged by the upstream vibro-feeder and moves them up to the shot-blasting machine. Placed in a pit, the first section is inclined while the second one is flat to allow operators to de-gate and sort castings in a safe and comfortable way. The last section is 30° inclined to load the continuous shot-blasting machine.

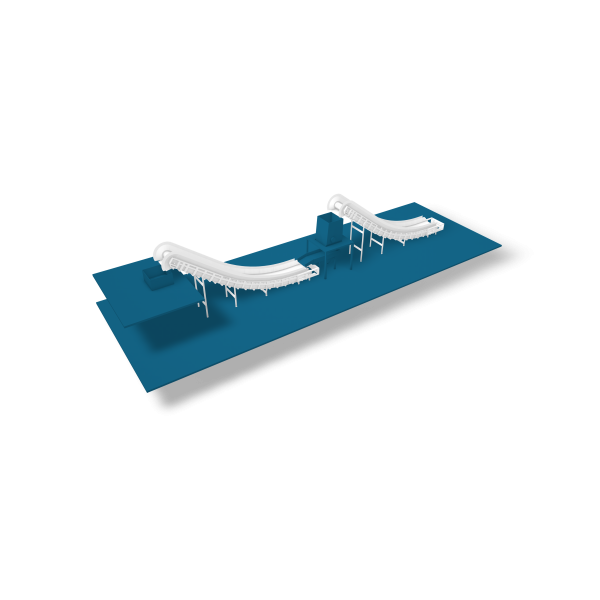

Italy

Blast loading & unloading

Iron foundry

The Superbelt conveyors allowed to transport castings to and away from the blast area, quietly and efficiently.

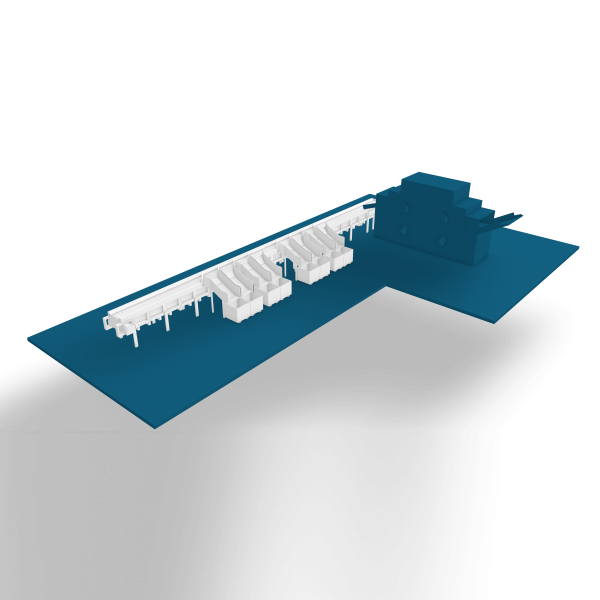

The Customer

Foundry specialized in manufacturing iron castings for several industries.

The Challenge

Magaldi served this foundry by supplying the entire conveying system upstream and downstream the shot-blasting machine.

The Solution

The first Superbelt® conveyor is installed downstream of the shake-out drum and transports castings up to the continuous shot-blasting machine. The gentle transport without vibrations allows keeping dust emissions under control.

Downstream the shot-blasting machine, a second Superbelt® conveyor allows workers to sort castings and remove sprues by means of hydraulic wedges.