The MADAM (Magaldi Dry Ash Management) system

Comprehensive solution for extracting, cooling, and treating dry Incinerated Bottom Ash, ensuring the maximization of overall economic and environmental benefits.

Incinerated Bottom Ash (IBA) is a valuable source of resources, such as ferrous, non-ferrous metals, and IBA aggregates.

The valorization of these secondary resources from IBA is gaining momentum as a crucial aspect of sustainable waste management in the waste incineration sector.

At Magaldi, we firmly believe that the dry IBA approach represents the future of the IBA treatment industry. This belief is driven not only by environmental considerations but also by the enhanced benefits it offers to plant operators and owners.

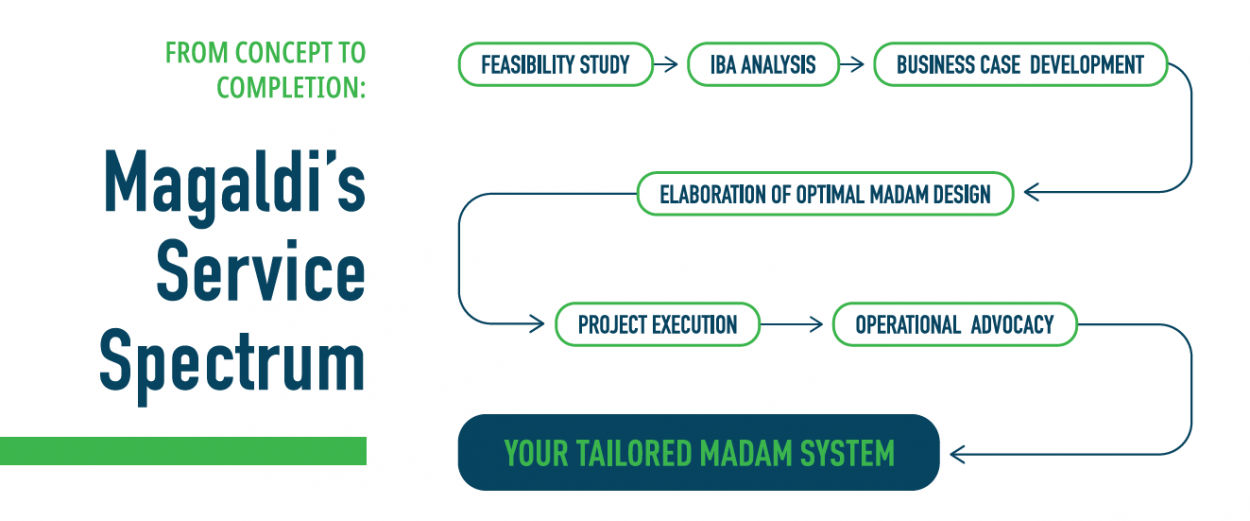

As a result, we have transitioned into a solutions provider, developing the MADAM system. It optimizes the entire chain, from the extraction of the IBA after the combustion process to the IBA treatment, generating valuable secondary resources while avoiding potential IBA landfilling.

Through a possible stepwise implementation approach, the MADAM system allows for a reduced initial investment and mitigates uncertainty associated with the heterogeneity of IBA composition. This results in a viable business case tailored to your specific needs.

Dry IBA extraction

The Magaldi Ecobelt® WA conveyor system is designed to extract, cool, and transport IBA using a fully dry approach, based on the use of a stream of ambient air as the primary cooling medium instead of water.

By combining the dependable Superbelt® conveying technology with the dry cooling process, the Ecobelt® WA overcomes the limitations of conventional wet ash extractors and provides significant advantages, including utmost dependability, zero water usage, no dust or gas dispersion during transportation, and reduced Total Organic Carbon (TOC) due to afterburning on the belt.

Discharging the IBA in a dry fashion also enables an increased recovery of metals during the IBA treatment process, which improves the quality of the IBA aggregates for further utilization purposes.

Dry IBA treatment

Dry IBA treatment in the MADAM system can take place on-site at the WtE plant or at a centralized IBA treatment plant to serve multiple incineration plants.

Compared to other treatment approaches, dry IBA treatment provides several key benefits, such as:

Increased metal recovery

By having no contact with water, the metals in the IBA are not agglomerated into clusters by sticky, wet fine ash particles, and are more easily accessible by technologies such as eddy current separators.

In addition, the elimination of any moisture in the IBA allows the recovery of metals down to a size of 0.2 mm. This increases the amount of recovered metals and reduces at the same time the pollution of fine heavy metals during the utilization or landfilling of the treated IBA aggregates afterward.

Increased revenue

While finding precious metals especially in the finer fractions, having an enhanced recovery efficiency in this fraction increases your revenue significantly.

Greater ecological savings

Recovering secondary materials from IBA allows you to substitute their primary production. In this way, treating IBA can save up to 1 ton of CO2eq. for every ton of treated IBA.

Wider range of design possibilities compared to wet treatment technologies

As there is no moisture in dry discharged IBA, dry IBA treatment has the ability for different levels of automation, continuous flow, and purification of the metal product. This is only possible thanks to no moisture within the IBA, generating consistent material properties, and easier quality control.

Dust-free environment

Dry IBA treatment ensures a dust-free environment for workers as it operates within a fully enclosed system.

Reduced labour

Having the ability to automate your systems allows the integration of IBA treatment into your daily WtE plant activities, which can lead to reduced labor requirements.

Not sure if investing in IBA treatment is worth it?

Magaldi has developed the ASH INSIGHT UNIT - a mobile test facility that brings the laboratory directly to your WtE plant, delivering real-time, on-site data on the true potential of your ash.

No shipping.

No waiting.

No guesswork.

The system is up and running in just one day.

Operators can perform:

- On-site, real-time assessment of IBA under actual operating conditions

- Dry processing of wet IBA to determine the optimal recovery potential

- Quantification of non-ferrous metals <20 mm - where 70-80% of revenue potential is concentrated

- Large sample analysis (up to 1000 kg) for statistically robust results

- Ferrous content estimation

- Particle size distribution analysis for accurate system design and economic forecasting

From data to decision, the Ash Insight Unit turns uncertainty into clarity, paving the way for the scalable deployment of the MADAM dry IBA management system - supporting a stepwise approach from pilot projects to full-scale implementation.