Engineered to meet the demands of modern cement manufacturing, the Magaldi Calcined Residues System (MCRS) provides a patented solution for the continuous extraction, cooling, and safe handling of hot calcined residues that accumulate at the bottom of the tertiary air duct, close to the precalciner.

Continuous Extraction & Cooling

Based on the exclusive Magaldi Ecobelt® technology, the system continuously extracts and cools down the hot residues through a controlled flow of ambient air, leveraging the negative pressure within the tertiary air duct.

Enhanced Energy Efficiency

through Heat Recovery

The MCRS recovers the sensible heat from the cooled material and feeds it back to the precalciner, reducing overall fuel consumption. It also promotes the conversion of the unburned particles within the residues, thus recovering the chemical energy and further improving the process efficiency and supporting the plant sustainability goals.

High-Temperature Resistance

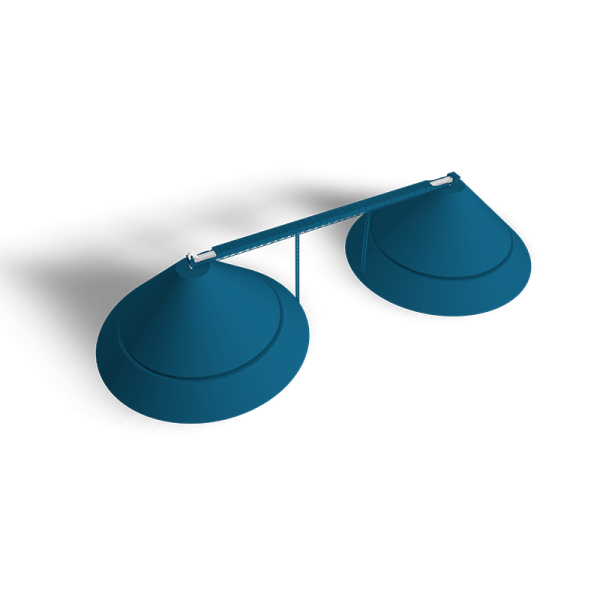

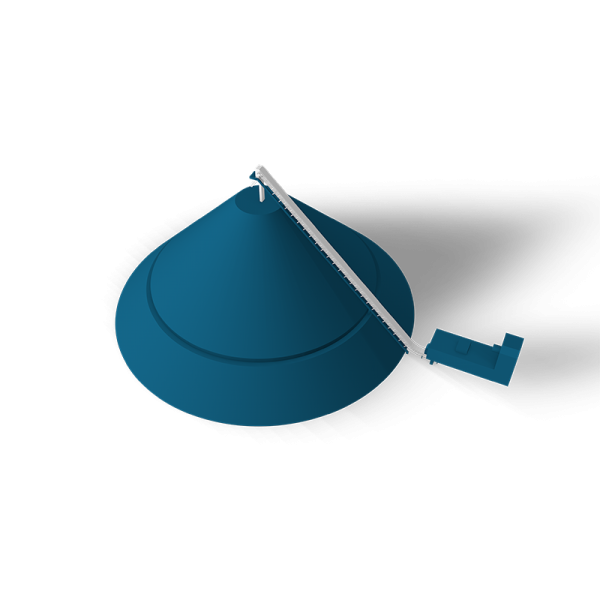

Designed for harsh operating environments, the MCRS withstands material temperatures ranging from 800 °C to 900 °C. Its patented pan-to-mesh belt connection system allows unrestricted thermal expansion of components, preventing any permanent deformation and maintaining long-term mechanical integrity.

Reliable & Safe Operation

Designed with operational reliability in mind, the system effectively and safely handles residues that may contain unburned particles and foreign pieces, including tramp metals. Such challenges are common when burning alternative fuels such as RDF or TDF.

By preventing accumulation and blockages in the tertiary duct, the system ensures that the process complies with strict safety and environmental standards.

Material Processing & Recycling

Downstream of the cooling stage, the residues can be screened and reduced in size. Fine material is conveyed back to the rotary kiln for reprocessing, while the oversized fraction is safely diverted to an enclosed three-wall pit or sealed container for proper disposal, thus promoting resource efficiency and waste minimization.

Low Wear &

Maintenance Requirements

Calcined residues are inherently abrasive, which can lead to rapid wear of system components.

The conveyor system’s low-friction design minimizes wear on moving parts, resulting in extended service life and lower maintenance requirements for conveyor components.

Dust Containment

To prevent false air from entering the system, which could disrupt the kiln feed balance, the conveyor is completely enclosed in a steel casing. This design enhances environmental compliance and process efficiency.