Solutions provider for coal-fired power plants

Energy-efficient and environmentally responsible dry bottom ash handling systems are the logical choice for companies looking to comply with new environmental standards and achieve cost savings.

Magaldi pioneered the application 40+ years ago, developing dry bottom ash conveyor systems that operate without any water requirement and deliver a dry, lower carbon content ash that can be used for gainful purposes instead of being disposed of.

Its patented systems offer many advantages and cost savings over traditional wet ash handling systems:

- High reliability, uptime, and operational performance

- No requirement of water for ash cooling and conveying

- Lower operating costs

- Higher boiler efficiency

- Process environmental sustainability

- Marketable ash (low amounts of carbon or LOI).

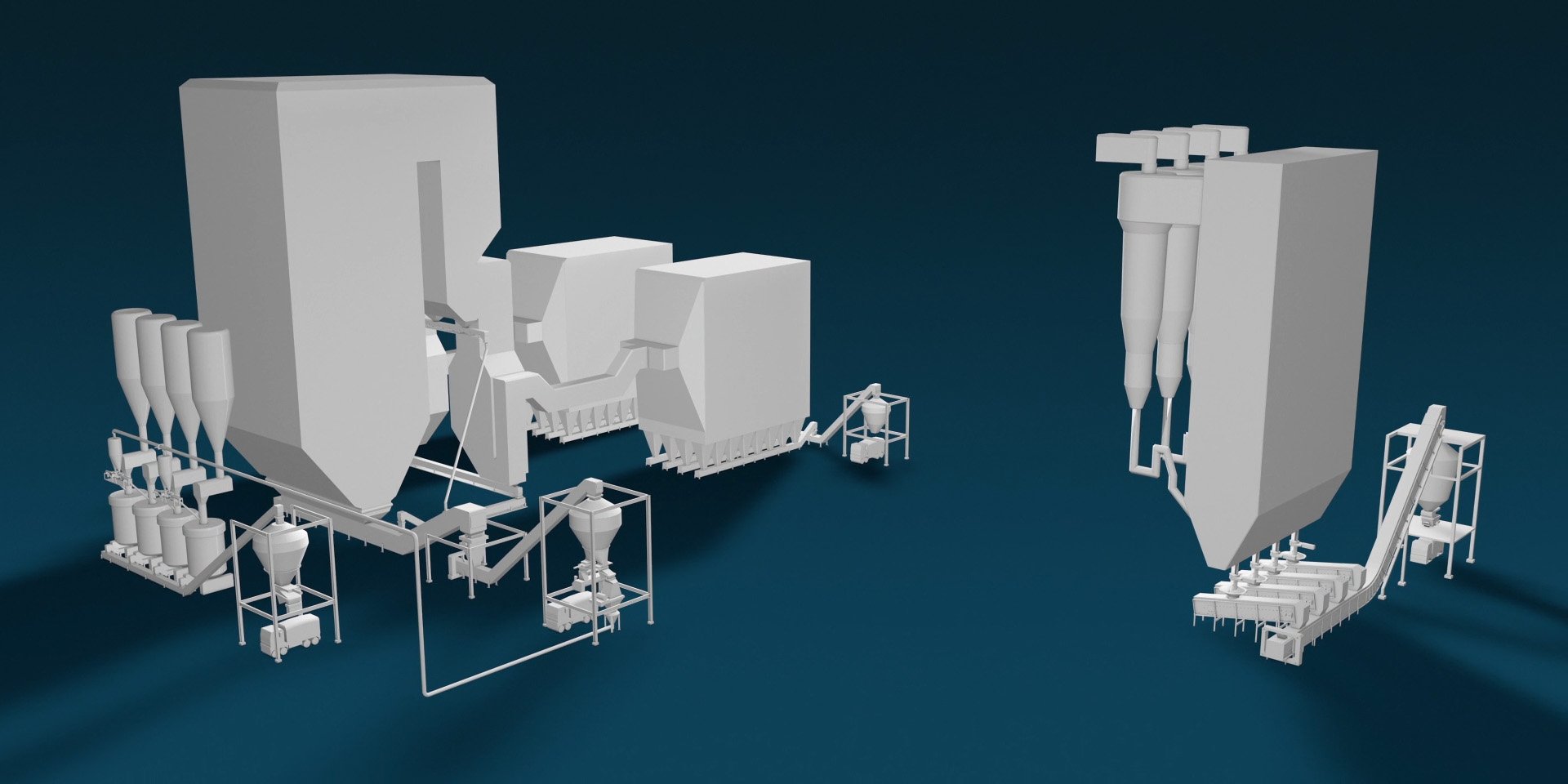

PC Power Plant

FBC Power Plant

mechanical handling

post combustion

Dry fly ash handling system

Coal-fired power plants

The Ecobelt® FA system provides the mechanical transport of fly ash from storage hoppers to storage silos.

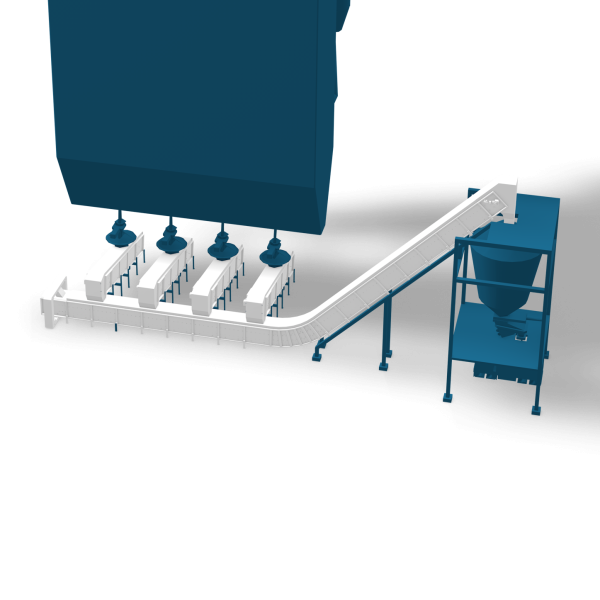

Fluidized bed ash extraction system

Coal-fired power plants

The FLUIMAC® system allows dry extraction, air cooling, and mechanical handling of bottom ash from fluidized bed boilers.

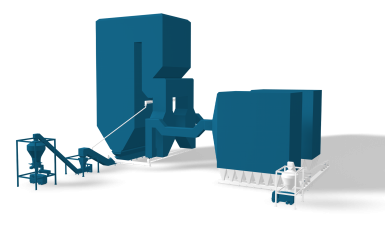

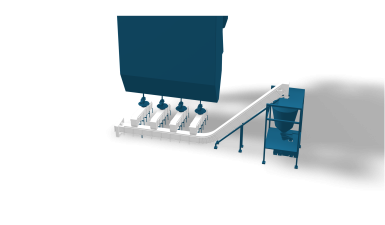

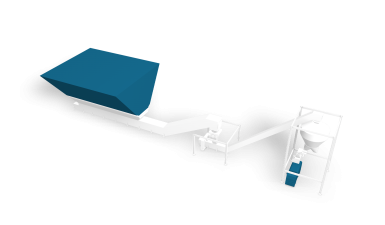

Dry bottom ash handling system

Coal-fired power plants

The MAC® system allows dry extraction, air cooling, and mechanical handling of bottom ash from pulverized coal-fired boilers.

Dry bottom ash postcombustor

Coal-fired power plants

The MAP® system allows to enhance and control the post-combustion of unburned carbon (UBC) in the ash.

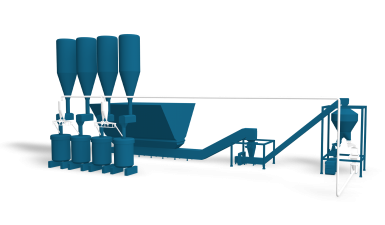

Dry Bottom Ash Recycling system

Coal-fired power plants

The MAR® system allows for turning bottom and ECO ashes into saleable fly ash.

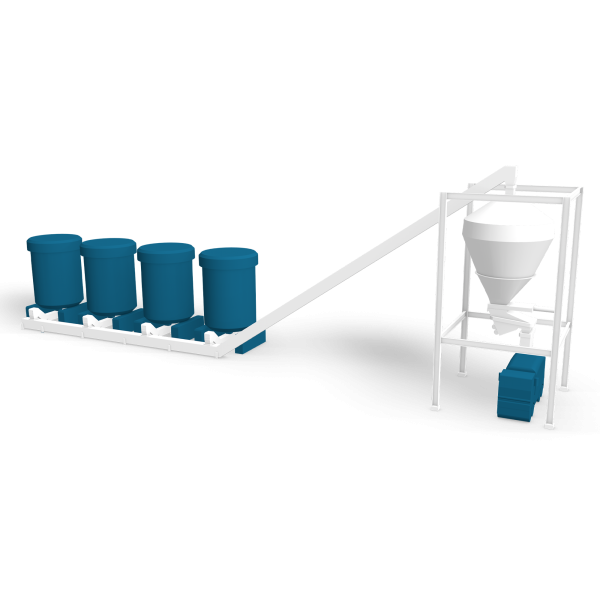

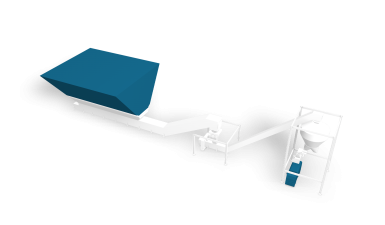

Dry Mill Rejects Handling system

Coal-fired power plants

The MRS® system allows the dry, mechanical handling of rejects from coal mills.

Dry bottom ash handling system for high-ash content coals

Coal-fired power plants

The SuperMAC® system allows dry extraction, air cooling, and mechanical handling of bottom ashes from boilers that burn low-ranking coals.

An installed base of 1,500+ machines and systems worldwide