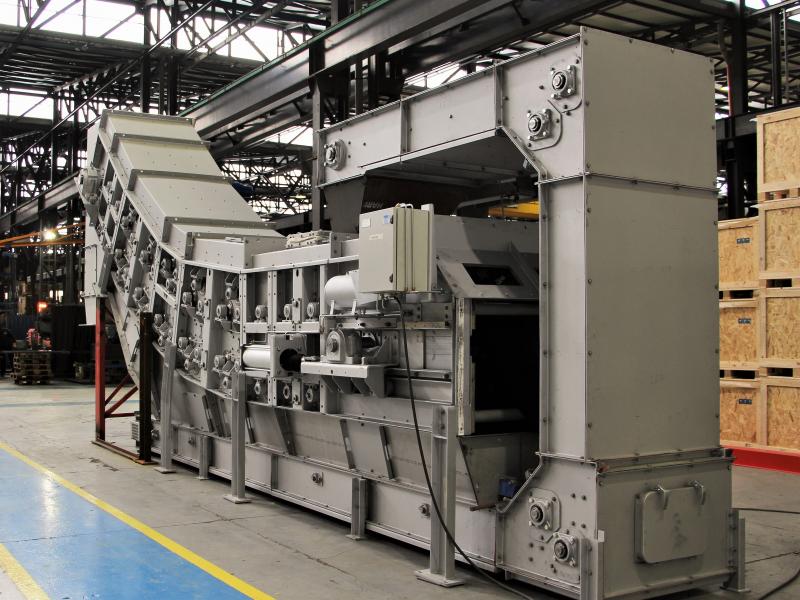

The Ecobelt® B conveyor

Designed for critical applications with dusty, abrasive, and hot materials across highly inclined paths

This belt bucket conveyor is generally used in cement plants to transport hot clinker from the kiln cooling system to the silo, in a safe and environmentally friendly way, even in the case of conveying routes with up to 75° inclination.

Its full reliability comes to force when replacing Apron-based or pan conveyors, suffering from high operating costs or harsh and frequent maintenance problems.

High reliability

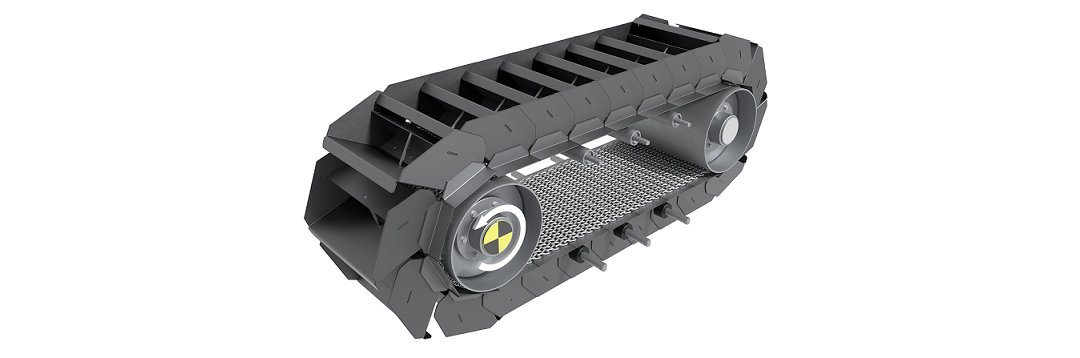

The Ecobelt® B conveyor features buckets securely bolted on a patented steel double-wire mesh system. The belt damage-tolerant design is based on a multi-link concept: the mesh provides redundancy, little to no maintenance, and trouble-free continuous operation. Even in case the mesh gets severely damaged, the conveyor will keep running till the scheduled maintenance, without sudden failures.

The trouble-free operation ensures productivity and profitability and results in greater efficiency and uptime during a 24/7, year-round process.

High conveying capacities

The unique interlocking design of the buckets (up to 1,600 mm wide) maximizes the conveying area, ensuring high capacities.

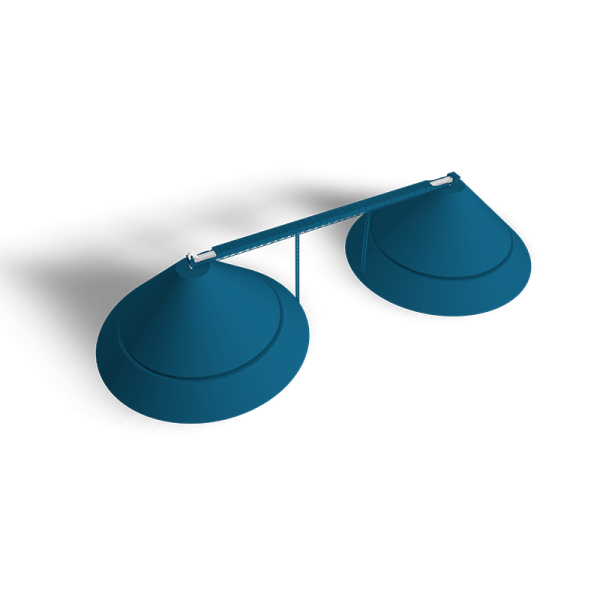

Suitably selected feeding equipment and chute provide a uniform bucket filling and an even material distribution over the entire width.

High temperature resistance

Downstream the kiln cooling system, clinker can be still hot.

With the Ecobelt® B conveyor, high-temperature issues are solved thanks to the patented method of connecting the buckets to the mesh belt, which leaves all components free to thermally expand in any direction without permanent deformation. As a result, the conveyor is able to withstand temperatures of up to 1,100 °C.

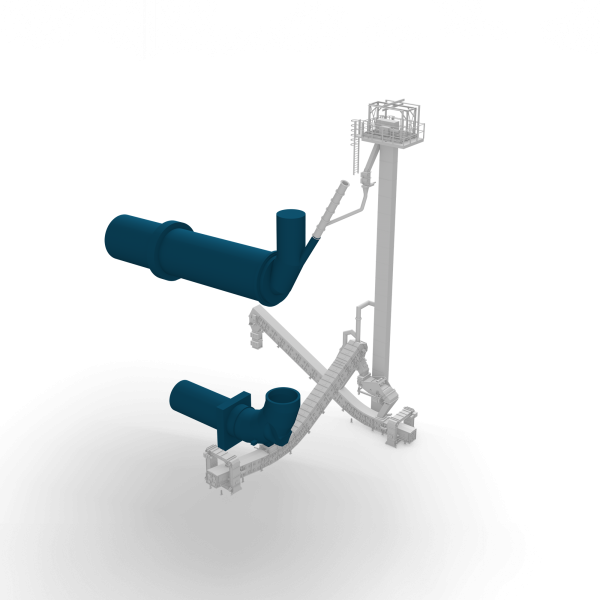

Steep inclines

The Ecobelt® B conveyor fits into the most complex layouts, combining high elevation (inclination of up to 75°) with restricted space. The result is a drastic reduction in the overall footprint required for installation.

Reduced dust emissions

The Ecobelt® B conveyor is fully enclosed in a steel casing, which prevents the clinker from exiting and minimizes the escape of dust.

Quiet operation

With a noise level of <75 dB(A), the Ecobelt® B conveyor is less than half as loud as conventional Apron conveyors with chains. The lack of chains and sprockets (and the related mechanical engagement) as well as the highly smooth running reduce noise emissions considerably.

Negligible wear

The Ecobelt® B conveyor is much less susceptible than chain bucket conveyors to wear and tear as it runs on smooth sealed idlers with bearings (no wear bars).

Also, the unique seal between the buckets avoids any crevice into which abrasive material can find its way. This minimizes abrasion wear effects, promoting increased uptime and less frequent purchases of worn parts.

Low maintenance requirements

The steel casing does not affect the maintainability of the conveyor system.

The Ecobelt® B runs on idlers with external bearings, allowing for safe inspection and lubrication with the conveyor in operation. The other elements are designed for continuous operation and can be checked during preventive maintenance over a multi-year schedule.

Optional material weighing

If requested, continuous product weighing is possible. In such a case, the conveyor is equipped with load cells installed on the supporting structure of the carrying idlers to measure in real-time the mass of the transported material.

-

Download our catalog for more information

PDF - 1.08MbDownload

Some successful stories

Ivory coast

Hot artificial pozzolana handling

Cement plant

The Ecobelt® bucket conveyor has proven to be successful in conveying hot, abrasive, and dusty materials over steep inclinations.

The Customer

Grinding plant.

The Challenge

Provide a conveyor capable of steep inclinations and reliable transport of artificial pozzolana at 700°C.

The Solution

Magaldi provided a bucket conveyor – the Ecobelt® B – able to safely and reliably transport hot, abrasive, and dusty material, climbing an incline of up to 75°.

Fully enclosed in a steel casing, the Ecobelt® B conveyor ensures the dust-free transport of 50t/h of artificial pozzolana discharged from the kiln at 700°C.