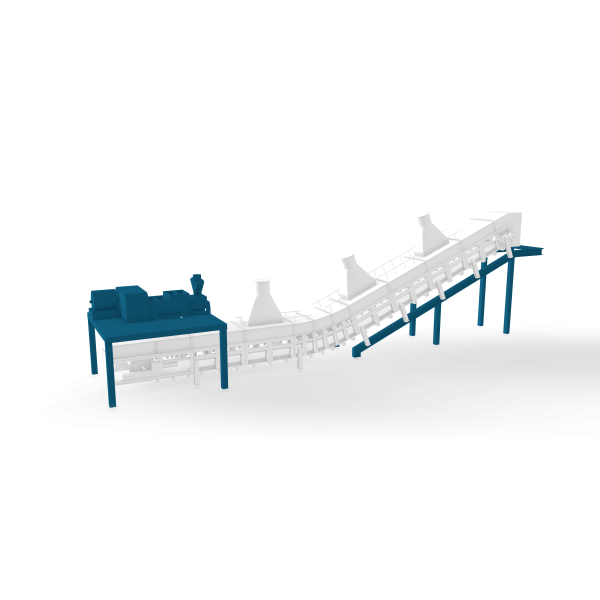

The Ecobelt® DRI conveyor

A dependable solution for cooling and transporting hot DRI

In the most common direct iron reduction processes, hot DRI (HDRI) is fed into the Electric Arc Furnace (EAF) through gravity systems, pneumatic, or mechanical systems.

The distance between the shaft furnace and the EAF is crucial when selecting the most suitable conveying system:

- If the distance is less than 40m (130 ft), gravity systems are most likely to be used;

- If the distance is in the range of 40 to 200m (130 to 650 ft), the mechanical system is the suited solution;

- for distances longer than 200m (650 ft), or when the EAF is not close enough to use alternative methods, a vessel will be used to transport HDRI.

Among the mechanical systems, the Ecobelt® DRI conveyor stands out for high-temperature resistance, smooth running, safe operations, long service life, and reliability with low need for maintenance interventions and relative costs.

High reliability

The Ecobelt® DRI conveyor features partially overlapping steel pans or buckets, securely bolted on a patented steel double-wire mesh.

The belt damage-tolerant design is based on a multi-link concept: the mesh provides redundancy, little to no maintenance, and trouble-free continuous operation. Even in case the mesh gets severely damaged, the conveyor will keep running without sudden failures until the scheduled maintenance.

The trouble-free operation ensures productivity and profitability, and results in greater efficiency and uptime during a 24/7, year-round process.

Great flexibility

Due to its unique design, the Ecobelt® DRI conveyor provides the highest operational flexibility.

It can transport all kinds of HDRI (from fine-grained to lumpy materials) over different conveying paths. Depending upon the required inclination, the pans can be fitted with cleats (incline up to 30°) or replaced by steel buckets when conveying fines or round-shaped particles across steep inclinations (up to 75°). The use of buckets meets all requirements typically encountered for HDRI transportation, including the issue of material roll-back when the conveyor inclination exceeds 20°.

High temperature resistance

DRI is discharged from the shaft furnace at around 700 °C.

The Ecobelt® DRI conveyor can transport tough-to-handle materials at very high temperatures (up to 1,100 °C). The patented method of connecting the pans/buckets to the mesh belt leaves all components free to thermally expand in any direction without permanent deformations.

Also, the drive and carrying mechanisms are decoupled from the heated environment.

No DRI re-oxidation

No heat losses

As DRI is highly reactive and prone to re-oxidation when in contact with air, the Ecobelt® DRI conveyor is designed with an insulated cover and equipped with an inert gas system (by off-gases, nitrogen, etc.). The integrated seal gas system keeps the oxygen out of the DRI and assures an inert atmosphere at any point in the conveying area. As a result, the risk of re-oxidation tends to zero, and the material is transported without losses in the level of metallization. Also, to minimize the demand for inert gas, the conveyor is equipped with unique skirtboards that contain gas leakage.

Regarding heat losses during material transport, the inner walls of the casing are coated with suitable insulation. This means that DRI can be charged into the EAF while still hot, thus allowing to reduce the required melting time while saving energy.

Reduced dust emissions

When transporting HDRI, it is crucial to avoid any release of dust into the environment and prevent material spillage underneath the conveyor.

With the Ecobelt® DRI conveyor, the smooth running and the absence of relative motion between the material and steel pans/buckets ensure that no additional fine particles are generated, and no spillage occurs. Moreover, the conveyor is coupled with a dedicated dedusting system to keep dust under control and reduce explosion hazards.

Low maintenance requirements

As there are no chains, wheels, or sprockets, the only points requiring lubrication are head and tail pulley bearings and return idler bearings. Upper idlers and rollers are lubricated for life. Other elements are designed for continuous operation, and preventive maintenance can be carried out over a multi-year schedule.