The Supercinghia

Extreme cut and rip resistance, low wear, and longer service life

Metal formers looking to maximize their production on high-volume parts can benefit from the unique Magaldi buffalo leather belt, the Supercinghia.

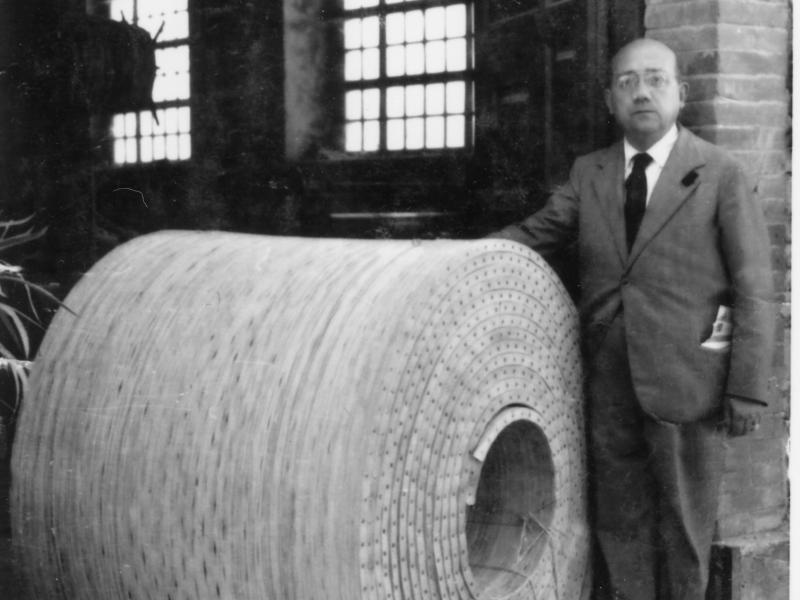

Designed and patented by Paolo Magaldi at the beginning of the 20th century, the Supercinghia has lasted over time and resisted the relentless advance of technology, evolving from a power transmission belt to a bulk material handling system.

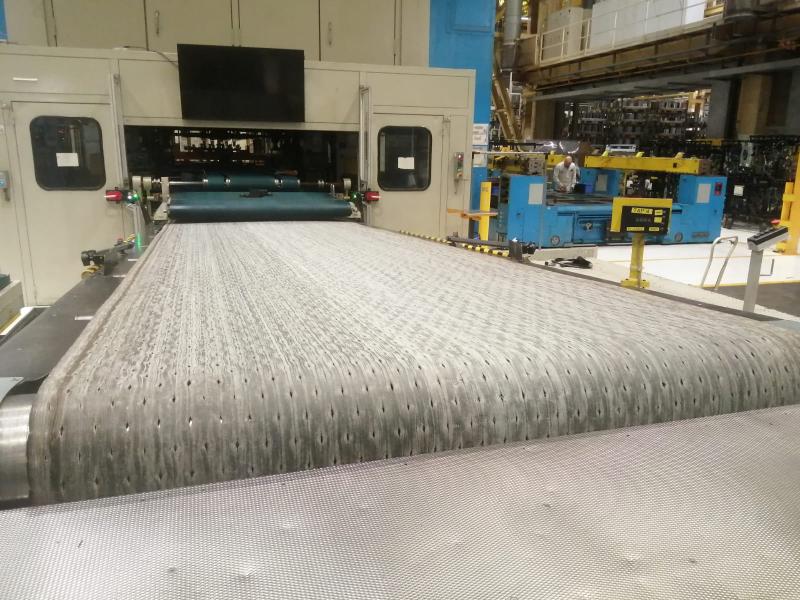

The Supercinghia is made up of buffalo leather strips placed side by side and held together by a steel pin set in a chessboard pattern. Each strip is obtained by cutting the tanned buffalo leather in a continuous spiral.

Stretching the strips and laying them side by side allows the belt to be as thick and large as required. The result is a unique design that ensures higher dependability as the belt cannot suddenly fail.

Cut and rip resistance

The Supercinghia is ideal for applications where extreme resistance to stresses caused by sharp-edged materials is required.

Conventional rubber belts are more prone to cuts and rips, responsible for the belt rupture and consequent production line stoppage. On the other hand, the unique assembly design of the Supercinghia provides outstanding reliability. Even if an accidental cut affects one or more strips, the rip won’t spread across the entire belt width, ensuring continuous operation. Damaged strip replacement can be postponed and carried out during scheduled maintenance interventions.

Wear resistance

The Supercinghia also provides excellent wear resistance thanks to the chemical treatment (chrome tanning) carried out on the leather.

The ability to resist abrasive wear determines its operational lifetime and, therefore, its value for money.

Reduced maintenance costs

Unlike rubber and PVC belts, the Supercinghia does not require the full belt replacement in case of damage. The chance of replacing only the damaged strips significantly reduces maintenance time and costs.

Longer service life

The Supercinghia has an expected lifetime far longer than any other conventional belt. It can last up to eight to twelve times longer than others since it is the only belt that can be used until it is completely worn out.

Magaldi offers a 5-year warranty on the Supercinghia, although several references have proven that its service life is much longer (on average 15 years). There is simply no comparison with conventional rubber or fabric belts.

Fields of application

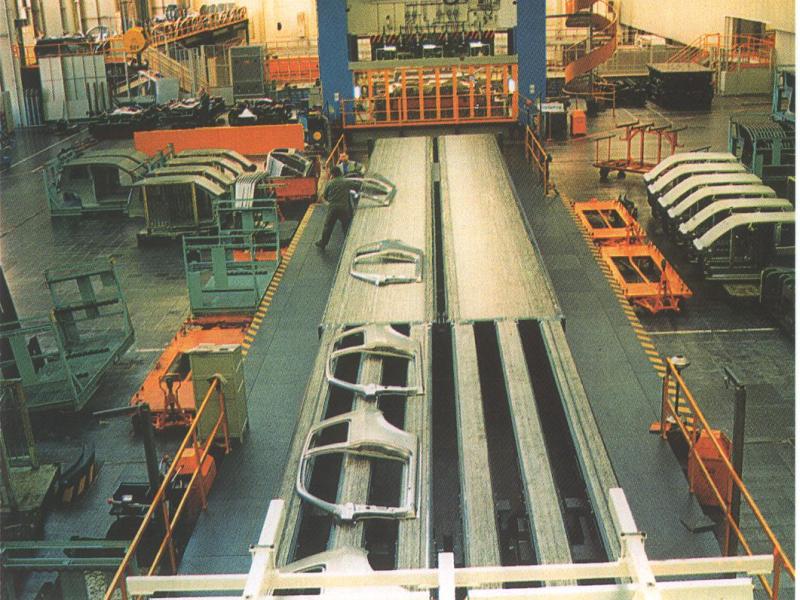

Durability and reliability make the Supercinghia ideal for industries whose production processes are on a continuous basis, and whose productivity depends on the conveyor belt reliability.

Typically, the Supercinghia is employed in:

- Stamping conveyor lines (thickness 0.2 – 25 mm)

- Metal sheet conveying

- automotive industry for conveying pressed body parts, cold rolled products, pickled sheets, and rolled aluminum sheets.

- Press shops as high timing press belt

- Inter-press and finishing line belt

- transfer press as ending belt

- cut-to-length lines

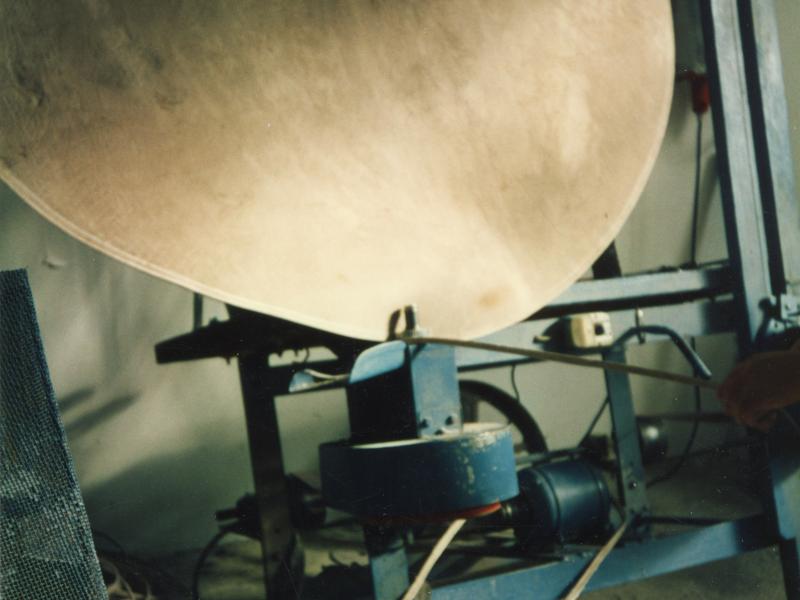

- coil wrapping machines.