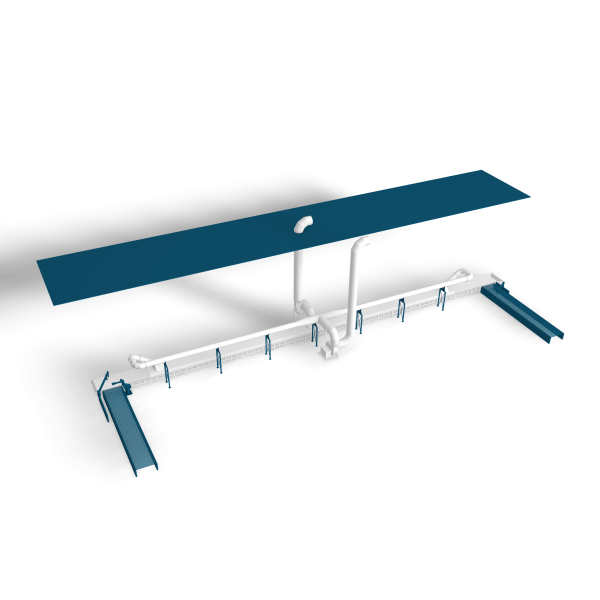

Solutions provider for forging plants

High performance in extremely hot material applications

Designed to operate flawlessly with extremely hot materials, Magaldi heavy-duty conveyors are ideally suited for the hot forging application.

Besides overcoming heat and wear-related issues, they also help the forging industry to become more energy efficient and environmentally responsible, by providing a range of benefits that set Magaldi apart from all the others:

- High reliability

- Increased uptime

- Class-leading performance

- Greater process streamlining and control

- Outstanding energy savings

- Low O&M costs

- Low noise emissions

- Safe operations

- Environmental sustainability

- Long service life.

An installed base of 1,500+ machines and systems worldwide