Solutions provider for biomass power plants

The paradigm shift from wet to dry ash handling systems underway in many coal-fired power plants and WtE plants is now also affecting the biomass industry.

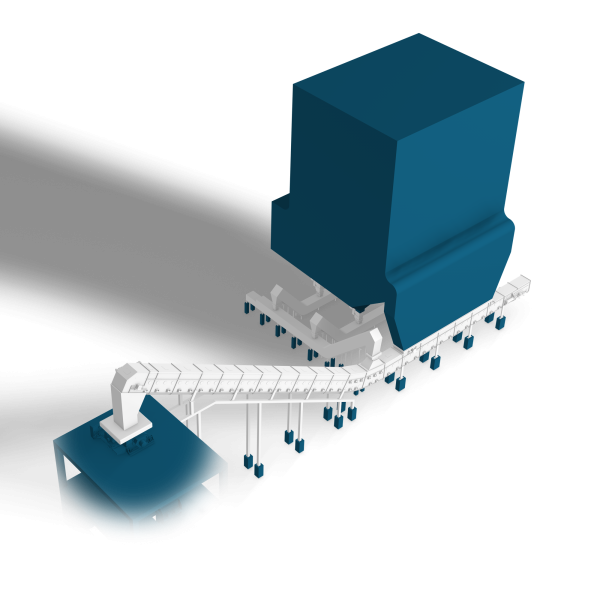

Magaldi developed an environmentally sound solution for grate-fired biomass combustion plants, to extract, cool and convey bottom ash without any water requirement and to deliver a dry, lower carbon content ash that can be used for gainful purposes instead of being disposed of.

Its patented system offers many advantages and cost savings over traditional wet ash handling systems:

- High reliability, uptime, and operational performance

- No water requirement for ash cooling and conveying

- Lower operating costs

- Higher boiler efficiency

- Process environmental sustainability

- Marketable ash (low amounts of carbon or LOI).

An installed base of 1,500+ machines and systems worldwide