The Magaldi Weigh Belt Feeder

Reliability and high accuracy in weighing and feeding, for optimized use of raw materials, monitoring of production processes, and high-quality sinter production

The production of high-quality sinter is crucial for assuring stable blast furnace productivity with low consumption of reductants.

Sinter quality begins with the proper selection and mixing of the raw materials (iron ore fines, limestone, return fines, slag-forming elements, and coke fines). Since the inhomogeneous raw mix can affect permeability and cause an increase in fuel consumption, proper dosing of the sinter feed composition is mandatory.

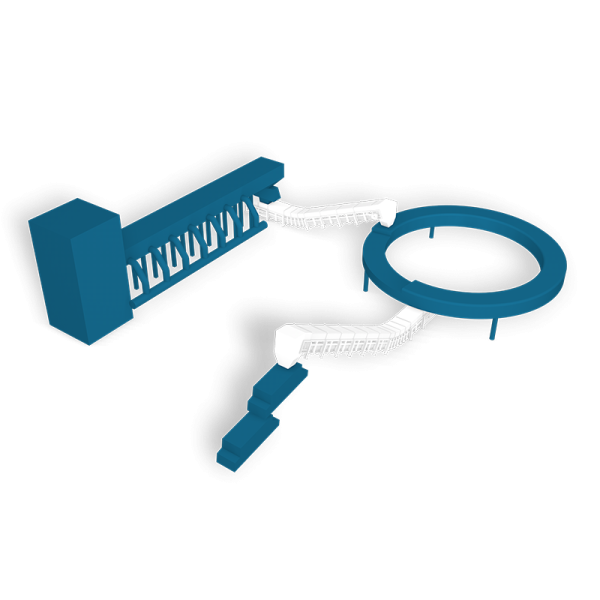

The Magaldi Weigh Belt Feeders allow for optimizing recipes, minimizing waste, and increasing productivity. Installed under the hopper of each storage silo, they are used to extract, continuously weigh and feed the mixing drum, where raw materials are humidified, homogenized, and granulated before sintering.

Thanks to the use of the Superbelt® conveyor technology, they offer superior resistance to shocks, high temperatures, and abrasion.

The Superbelt® conveyor is easily transformed into a weigh feeder through load cells installed on the supporting structure of the carrying idlers.

The actual feed rate is determined by combining the belt speed, monitored by an encoder, and the weight signal, given by the load cells. The controller automatically adjusts the belt speed to maintain the actual feed rate close to the set point value.

High reliability

The Magaldi Weigh Belt Feeder is crucial in production processes that require continuous weighing and dosing.

Thanks to the multi-link and damage-tolerant design of the Superbelt®, the belt feeder works reliably and without interruption. Even in the event of severe damage to the double-wire mesh, the conveyor will keep running until the scheduled stop for maintenance, without the risk of sudden failures.

Furthermore, the patented method of connecting the pans to the belt allows the transport of materials with temperatures of up to 1100°C, while a solid mechanical structure, designed to offer maximum strength and resistance to heavy loads, also guarantees reliable operation even in case of slag and dust contamination.

Accurate weighing

High-sensitivity load cells provide very high weighing accuracy (± 1-2%), allowing to optimize mixing and reduce waste.

Additionally, the availability of accurate information is essential to monitor the production process and identify potential improvements in order to produce higher-quality sinter.

Negligible wear

The Magaldi weighing equipment withstands harsh environmental conditions without any aging. The Superbelt® conveyor is designed to avoid sliding friction among the moving parts, thus minimizing equipment wear even when transporting high abrasive material.

The negligible wear results in revenues in terms of lower maintenance and spare parts requirements.

Reduced dust emissions &

Very quiet operation

The Magaldi weigh belt feeder has also a safety-critical function as it avoids spills. The smooth running without vibrations minimizes dust generation, while the steel casing prevents material/dust spillage into the environment. It, along with a noise level <75 dB(A), results in a safer and healthier workplace and allows overcoming many threats to profitability, including the potential for lost material, housekeeping costs, risk of injuries, and increased unexpected downtime.

Low maintenance requirements

Difficult access to equipment and fast production rates dictate minimum time windows for maintenance, inspection, and repair. For such reason, Magaldi designed a weighing system that works virtually maintenance-free for many years. As there are no chains or sprockets, the only points requiring lubrication are the bearings of the head and tail pulley. The other components are designed for continuous operation and can be checked during preventive maintenance over a multi-year schedule.

Extra long service life

The conveyor is backed with a 3 to 5 years warranty, but its expected lifespan is longer.

Just think that a Magaldi weigh feeder installed in a plant in Sardinia (Italy) has been operational since 1981 with the original belt. In its 40+ years of operation, the machine has handled 33.600.000 tons/h of abrasive material without ever requiring belt replacement.