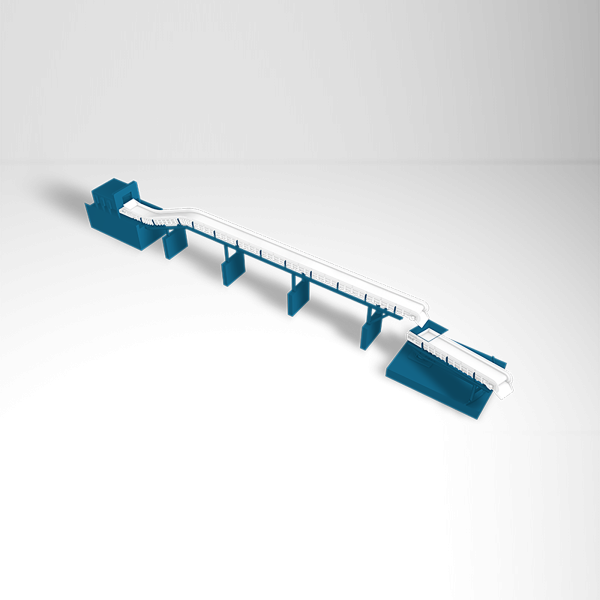

The Ecobelt® conveyor

An environmentally sound solution for transporting ladle slag while reducing powder dispersion

Recycling steelmaking slags has become a key issue to close the sustainable production loop.

Ladle furnace slag – also called ‘white slag’ due to its high content in calcium oxide – can be successfully recycled as a flux in secondary steelmaking, or routed to other industries (i.e. cement) as raw material.

Despite its potentiality, the valorization of LF slag is difficult due to the disintegration phenomenon. During the cooling and conveying operations, this heterogeneous and hard-to-handle material disintegrates into fine dust, placing severe handling and environmental problems.

To deal with this issue, the slag is usually sprayed with water to accelerate the cooling process and form a wet material that is not dusty to handle. However, the use of water has an adverse impact on the environmental footprint and causes the lime within the slag to hydrate, which substantially reduces the potential value of this material as a lime substitute in the metallurgical process.

To overcome those drawbacks, Magaldi designed the Ecobelt® conveyor, which allows for the dust-free transport of LF slag while providing added cooling without any use of water.

High reliability

The Ecobelt® conveyor features partially overlapping steel pans securely bolted on a patented steel double-wire mesh system.

The belt damage-tolerant design is based on a multi-link concept: the mesh provides redundancy, little to no maintenance, and trouble-free continuous operation. Even in case the mesh gets severely damaged, the conveyor will keep running without sudden failures until the scheduled maintenance.

The trouble-free operation ensures productivity and profitability and results in greater efficiency and uptime during a 24/7, year-round process.

Reduced dust emissions

Dust is a very critical issue when it comes to handling LF slag.

With the Ecobelt® conveyor, the smooth running without vibrations minimizes dust emissions while the tight structure of the steel pans prevents any spillage thanks to the perfect fit in the overlap area.

Additionally, for more effective dust containment, the conveyor is fully enclosed in a steel casing that drastically reduces emissions to the environment.

High temperature resistance

Ladle slag is extremely hot, with average temperatures of up to 800 °C.

With the Ecobelt® conveyor, high temperatures issues are solved thanks to the patented method of connecting the pans to the mesh belt, which leaves all components free to thermally expand in any direction without permanent deformations. As a result, the conveyor can withstand temperatures of up to 1,100°C.

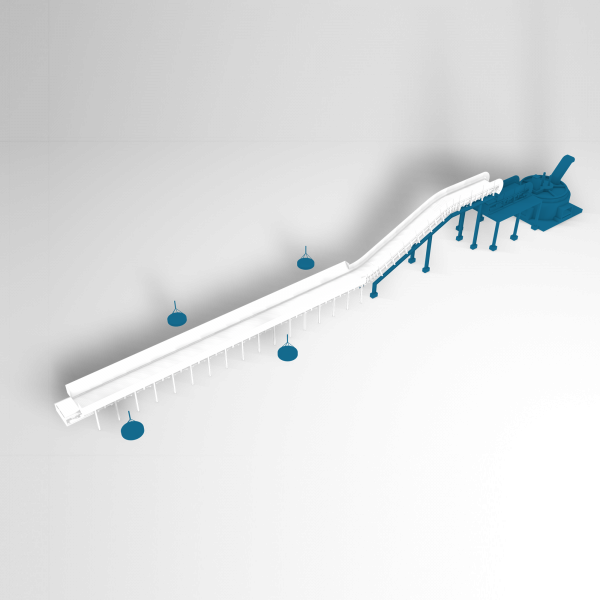

Air cooling

The Ecobelt® conveyor also allows for the air cooling of ladle slag during conveying. Inside the conveyor casing, a stream of air counter-flowing the transported material cools it down while preserving its chemical composition and, therefore, its valorization in the downstream steelmaking process.

Some successful stories

Italy

Ladle slag conveying

Steelmaking plant

The Ecobelt® conveyor allowed for an effective recovery and valorization of LF slag, which brought undeniable advantages in terms of environmental protection and economic benefits.

The Customer

Steel mill recently overhauled to comply with the highest safety and environmental sustainability standards.

The Challenge

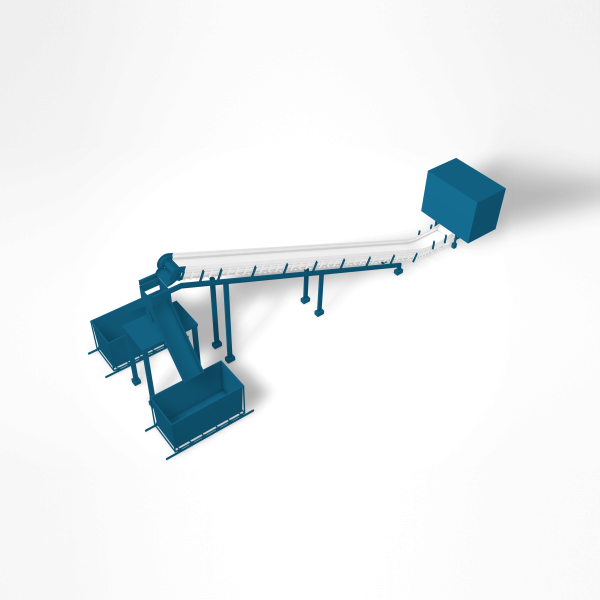

As a technology provider, Magaldi was involved in the “Zero Waste ” project, aimed at recovering 99% of waste from the manufacturing processes, to automate the transport of ladle slag and briquettes up to the EAF.

The Solution

In a dedicated area, ladle slag is cooled down and separated from the crust.

Loaded by a bucket elevator, an Ecobelt® conveyor transports the slag (sometimes still hot), along with briquetted iron, up to the EAF for re-melting. Fully enclosed in a steel casing, the Ecobelt® prevents dust spillage for a cleaner and safer work environment.