The Magaldi Aluminum Casting Cooler (MCC® AL)

Engineered and controlled air cooling of aluminum castings

Aluminum foundries are called upon to produce cast parts of consistently high quality and reduce scrap rates, to keep a competitive edge. Casting cooling is critical to achieving those goals and the success of the entire production process.

Magaldi tailored its field-proven cooling system developed for ferrous foundries to fit the unique requirements of aluminum castings. The MCC® AL conveyor offers great and controlled cooling performance that enables scrap reduction and high-quality parts manufacturing.

Working concept

The MCC® AL conveyor is comprised of:

- the Superbelt® conveyor as the key component.

The belt design is based on a multi-link concept which ensures redundancy, little to no maintenance, and trouble-free continuous operation, thus avoiding costly disruptions. - A cooling tunnel held under negative pressure.

A stream of ambient air is pulled through the extremities of the cooling tunnel and exits through the central hood. The cooling air flows at a controlled speed over the castings to cool them down to the requested temperature while avoiding thermal shocks and/or other microstructural defects. - An optical detector, ensuring the proper functioning of the belt at almost zero speed or batch.

Engineered cooling process

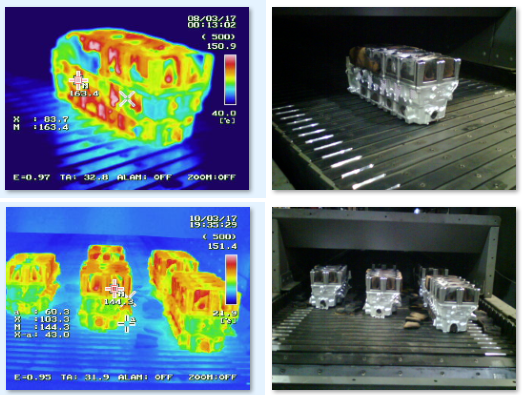

For each project, Magaldi thoroughly investigates the thermal properties both of air and castings to deliver the most efficient cooling process.

The combined use of analytical methods (CFD analysis), experimental tests on the in-house built test rig, and in-field measurements have allowed for very accurate thermodynamic models to be created and tested to ensure effective modeling and, ultimately, the cooling process.

High-quality castings &

Reduced scrap rate

The quality of aluminum cast parts largely depends on precise temperature control during cooling. Errors, failures, or inaccuracies have a direct effect on the quality of the cast product.

With the MCC® AL, castings are cooled down by precisely controlled quantities of air. The system uses in combination co-current and counter-current airflows for a more effective cooling which leads to a reduction in thermal stress, and the absence of cracks caused by uncontrolled shrinkage.

Reduced silica dust emissions

The MCC® AL conveyor also provides a competitive edge in dealing with a very sensitive issue, which is workers' exposure to crystalline silica dust.

Thanks to the Superbelt® conveyor, which runs smoothly and without vibrations, silica dust generation, and emissions are drastically reduced.

Integrated Supervision System (optional)

The MCC® AL conveyor can be integrated with the MISS®, a highly dynamic control system that reliably checks the cooling parameters and automatically adjusts belt speed and cooling rate to enhance the process.

Additionally, with the MISS® all process-relevant data are available. Once the parameters have been set, they are recorded and can be restored at any time. This means that the cooling process is reproducible and this, in turn, increases the quality of the cast parts and reduces expensive scrap.

Some successful stories

Mexico

Aluminum casting cooling

Aluminum foundry

The MCC® AL conveyors have the leading reputation as being dependable low-maintenance equipment with long service life.

The Customer

Leader in manufacturing aluminum components for powertrain and body structure applications.

The Challenge

The target for the foundry was to have castings under 100°C in a short window. Magaldi was asked to provide a reliable and easy-to-maintain solution.

The Solution

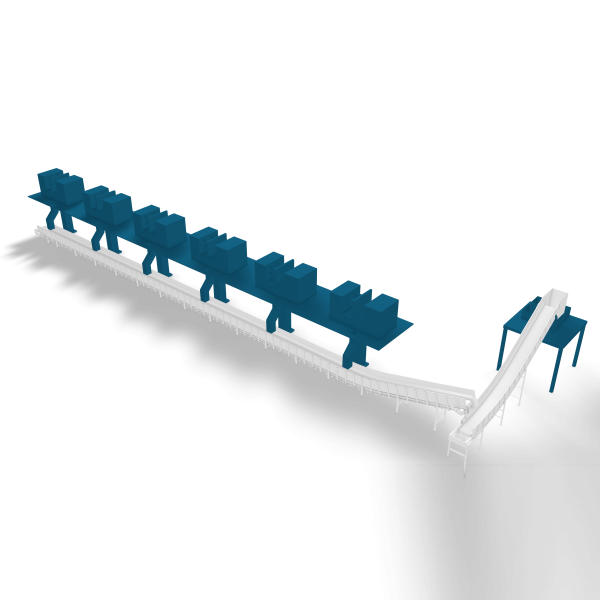

Installed downstream of the molding lines, 2 MCC® AL conveyors cool aluminum cylinder heads from 320°C to less than 80°C thanks to an enhanced air-cooling process. Belt speed and air capacity are studied to properly cool castings up to the required temperature, perfectly synchronizing with the upstream carousel.

Italy

Aluminum casting cooling

Aluminum foundry

Magaldi worked on thermal simulations with the aim of optimizing the cooling rate and accurately predicting the outlet casting temperature.

The Customer

Magaldi was awarded the supply of the casting cooling conveyors by an Italian company specialized in the construction of automatic robotic islands. The end-user was a Chinese aluminum foundry.

The Challenge

Magaldi was requested to supply 2 systems for casting cooling. A thermal analysis, validated by a three-dimensional CFD model developed in Ansys CFX, was conducted to customize the solution.

The Solution

The MCC® AL coolers transport 15 castings/h and cool them from 450°C to less than 100°C. Castings are loaded and unloaded automatically by means of manipulators.

Brazil

Aluminum casting cooling

Aluminum foundry

The MCC® AL has proven successful in ensuring high-quality cast parts, optimizing the overall process efficiency, and boosting the bottom line.

The Customer

Leading provider of light-weighting solutions for the global automotive industry, specializing in aluminum components for powertrain and body structure applications.

The Challenge

Magaldi had already supplied its cooling system to 2 of the Group's foundries in Mexico. The successful experience convinced the Customer to adopt this technology also in its plant in Brazil

The Solution

A robot moves the castings from a Rotocast moulding machine to an intermediate working station for de-coring and cutting activities. Once completed, the same robot places the castings on the MCC® conveyor. The latter cools the aluminum cylinder heads down from 450°C to < 150°C. Belt speed and air capacity are studied to properly cool castings up to the required temperature in harmony with the up-streaming Rotocast machine.