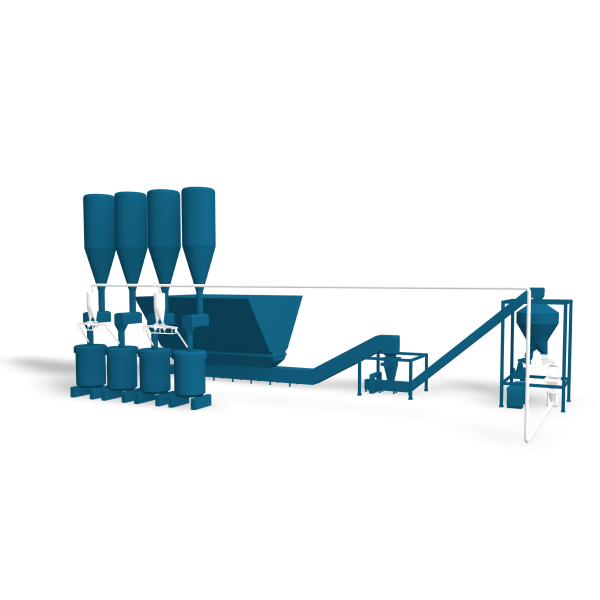

The SuperMAC® system

(Super Magaldi Ash Cooler)

Patented for dry extraction, enhanced air cooling, and mechanical handling of bottom ash from coal-fired boilers burning low-rank coals

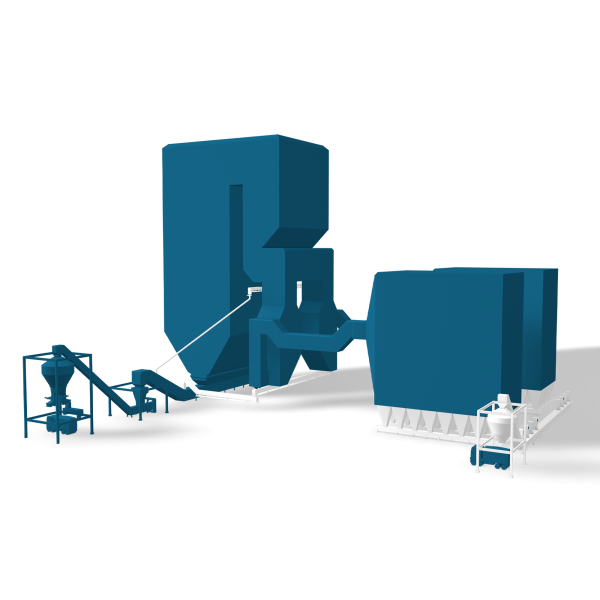

To extend the outstanding benefits of the well-proven MAC® system to those boilers that burn poor coals, Magaldi engineered the SuperMAC® system, designed with increased cooling capabilities and a unique system configuration that minimizes the required cooling air amount concerning the total combustion air rate.

It addresses the demand of coal-fired power plants for sustainable practices in bottom ash handling when burning high ash content coals (indigenous to India, South Africa, or Mexico) or other low-rank coals (lignite).

Dry vs. Wet

Unlike conventional wet bottom ash handling (WBAH) systems, responsible for huge water consumption, high maintenance costs, environmental issues, and negative effects on boiler operation, the SuperMAC® dry bottom ash handling system delivers a reliable, cost-effective, and environmentally friendly operation thanks to the unique combination of the dry cooling process and the dependable Superbelt® conveying technology.

Water & related cost savings

The use of the dry bottom ash handling system results in significant water and O&M cost savings. Since no water is used for ash cooling and conveying, pumps, piping, and water treatment systems are no longer necessary, and the associated costs are eliminated.

Based on the specific project needs, a minimum water flow can be used to reduce dust dispersion at the discharge point. The water rate can be controlled and set during operation.

Reduced disposal costs &

increased ash marketability

The implementation of the SuperMAC® dry bottom ash handling system greatly reduces ash disposal costs. The absence of water cuts the costs for landfilling due to a significant reduction in ash weight.

As a gainful alternative to landfilling, bottom ash can be sold to the cement industry since its features (dry and with lower unburned content) increase its saleability.

Increase in boiler efficiency &

environmental risks mitigation

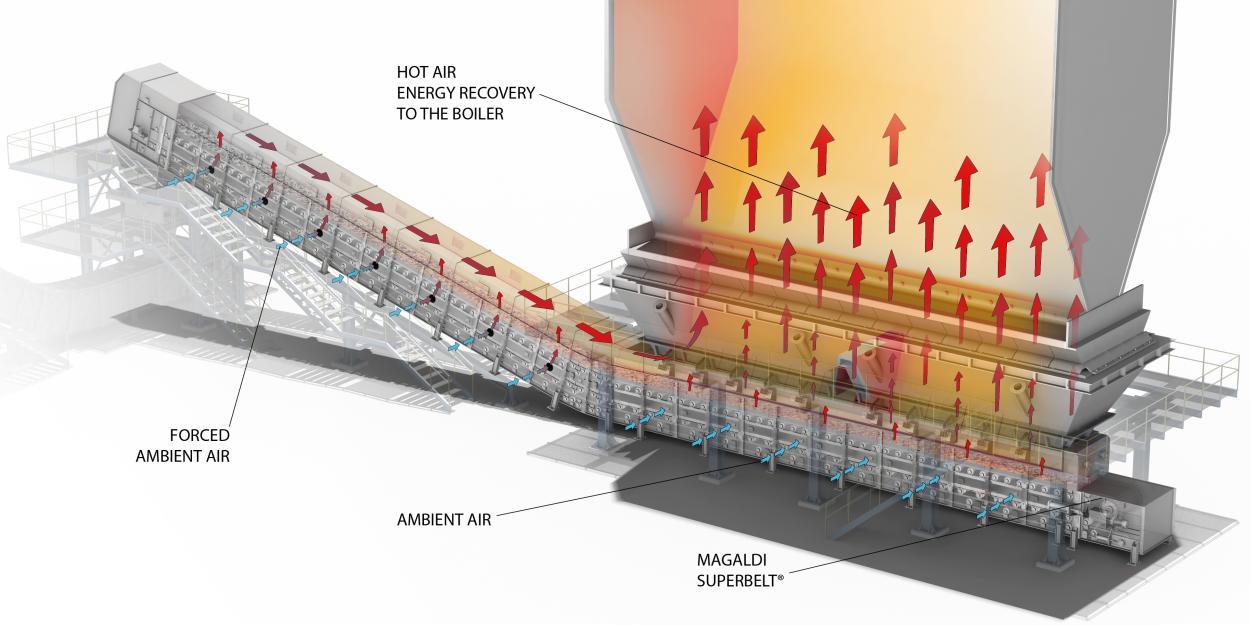

The SuperMAC® dry bottom ash handling system allows increasing the boiler efficiency by a factor in the range of 0.5÷1%, which can reach up to 2% (values calculated within the framework of ASME PTC4) in case of high UBC content in bottom ash.

As with the MAC® system, much of the heat leaving the boiler through the lower opening (radiant flux from the furnace, sensible heat, and the chemical energy contained in bottom ash due to its unburned carbon content) is recovered back by the cooling air which has become hot. However, thanks to the higher bottom ash to cooling air ratio and more effective heat exchange, the SuperMAC® can increase the boiler efficiency more than the standard configuration of the MAC® system.

The increase in boiler efficiency also results in lower coal consumption which, in turn, reduces CO2 emissions and ensures effective environmental risk mitigation.

Additional cooling &

transport to the final delivery point

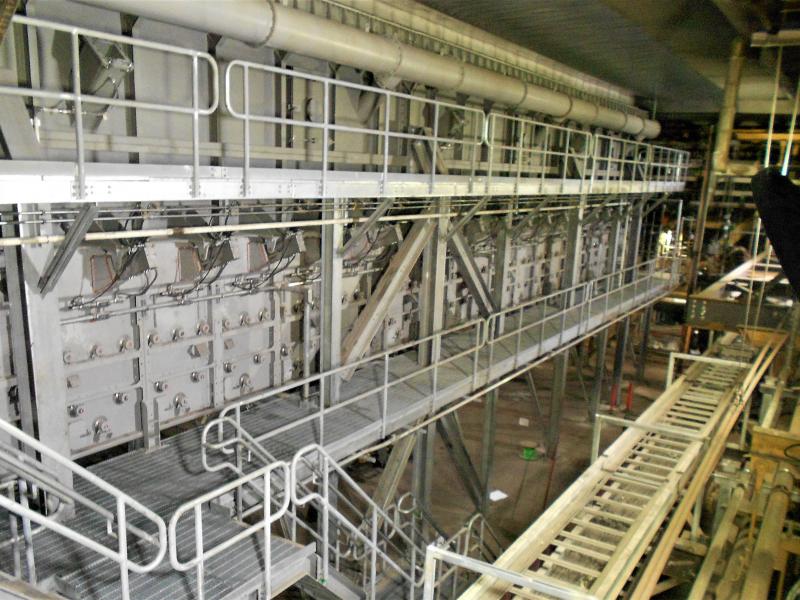

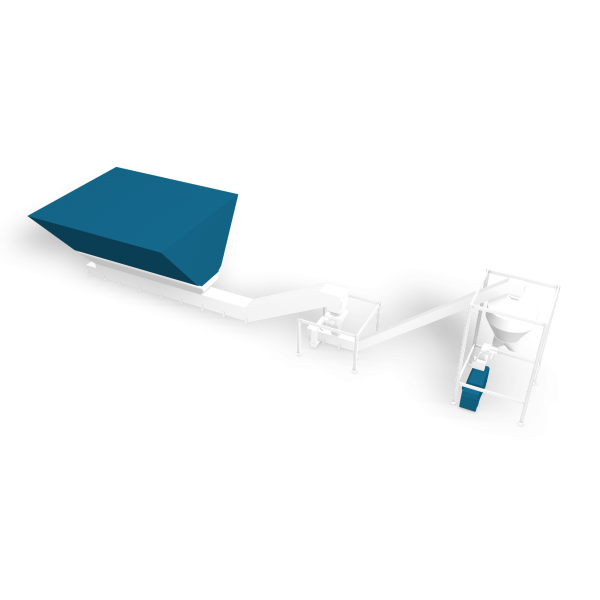

Typical SuperMAC® system configuration includes the Ecobelt® conveyor (Magaldi Postcooler) downstream the crushing stage. It is a secondary conveyor which provides further cooling while conveying bottom ash to the final delivery point.

Fully enclosed in a steel casing kept under slight negative pressure, the Magaldi Postcooler features a self-cleaning system that consists of some steel plates properly shaped and hinged to the belt. In the return part of the belt, the plates move the fines backward to the tail section of the conveyor where the Magaldi O-chain® reloads them to the main belt.

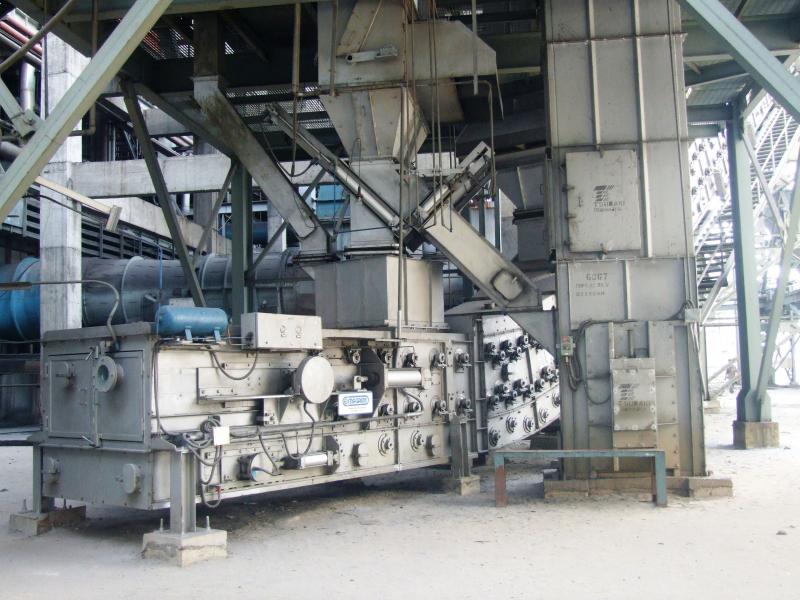

The Superbelt® conveyor technology

Apart from the overall benefits of dry over the wet system, the SuperMAC® system offers compelling benefits that derive from the use of the Superbelt® conveyor applied to dry ash handling, including:

- high dependability

- high temperature resistance

- high resistance to impact

- negligible wear and no tear issues

- low power demand

- low and easy maintenance

- weigh belt sections (as an option).